Both joy and sorrow for Ovum

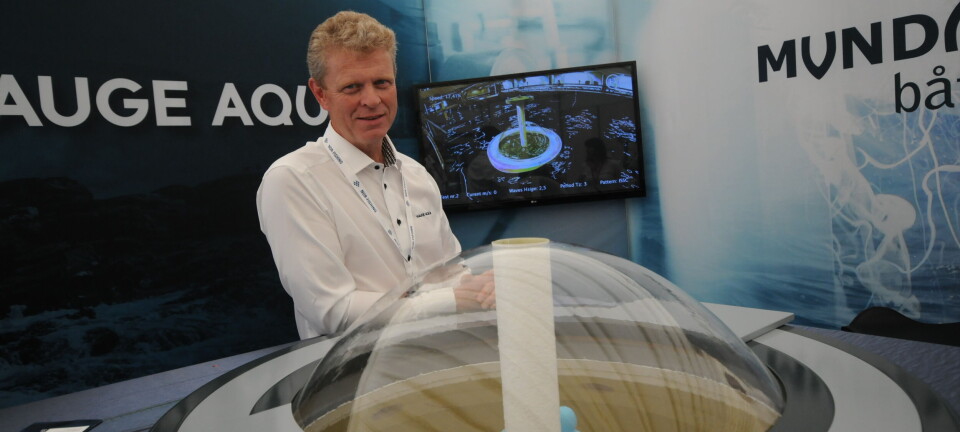

The company's chief executive Cato Lyngøy is pleased with technical milestones reached for the Egg floating closed containment system, but warns about the serious situation for manufacturer Herde Kompositt due to a lack of orders.

"We are lifting two completed post-smolt Eggs on to a barge today. One is a brand new E2000, and the other is the upgraded version of the pilot. Both are going to Gjermundnes in Romsdalsfjorden," Ovum chief executive Cato Lyngøy tells Fish Farming Expert's Norwegian sister site, Kyst.no.

Lyngøy, who is also the chairman of Herde Kompositt, says that it has been a busy autumn getting these two projects completed.

"We are incredibly proud of our team who managed to complete both projects within a tight schedule. Despite this important achievement, the situation is serious for Herde Kompositt going forward," he says.

Not giving up

He reports that unfortunately, the order book is thin going forward at Herde Kompositt, and lay-off notices have been sent out to over 50 of the company's employees, which has significant negative ripple effects for the local community in Ølve, in Kvinnherad municipality in Vestland county.

"At Ovum in Bergen, eight skilled employees have been laid off," he states.

Lyngøy says the companies are not giving up, and he is convinced that for the industry to grow, one must have floating closed technology as an alternative in many locations, to better take care of the salmon.

He states that Herde Kompositt is working very actively to secure other types of assignments.

"We find that many want to help us and come with relevant assignments or offers to hire personnel. Here, the close cooperation with the unions has been crucial. But so far, nothing has materialised into signed contracts."

Lean times ahead

He points out that Herde is a promising company with a lot of expertise.

"We aim to preserve that while we carry out a 'turnaround' and establish more pillars to stand on. We have had plenty to do with the Egg assignments up until now, but going forward, it is quite dry."

The new Egg built at Herde Kompositt is the same size as the pilot: 2,000m³, 21 metres high, and 15 metres wide.

"The good biological results from the first fish productions, together with over 150 systematised learning points, provide us with a solid foundation for scaling up to 20,000m³. We have now also incurred the cost of bringing the pilot ashore. This gives us good insight and risk reduction for our technology and for customers in the next round," says Lyngøy.