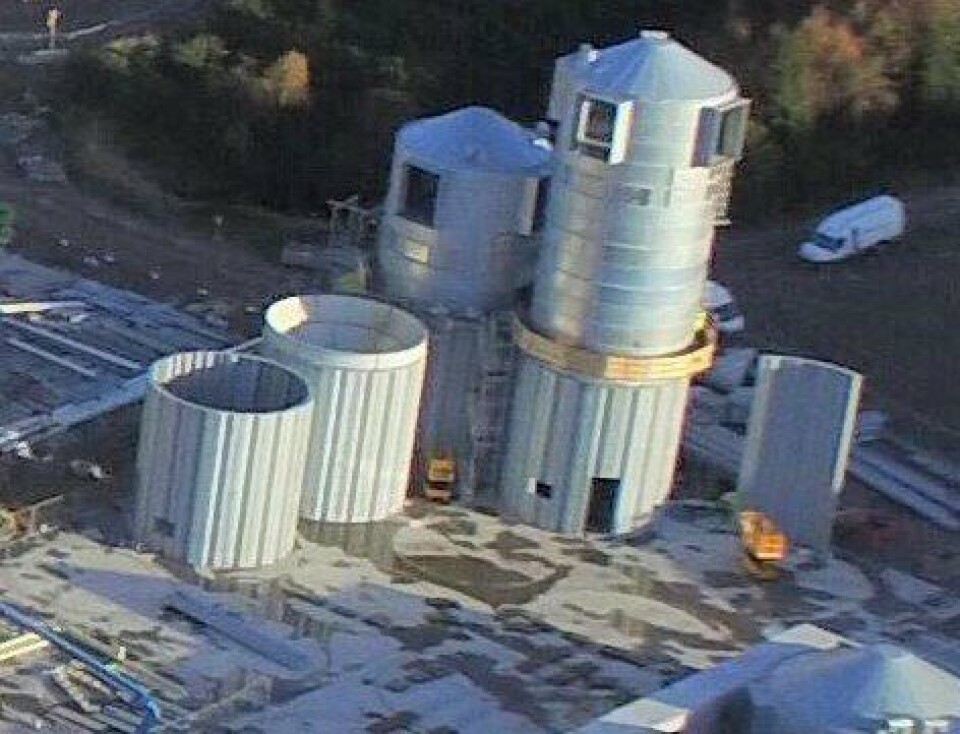

Marine Harvest feed plant from high in the Skye

Marine Harvest's £93 million feed plant at Kyleakin on Skye is rapidly taking shape, as a new photograph taken from a drone shows.

"Things are moving very fast with the construction," said MH environment manager Chris Read. "The steel frame that you can see in the picture is the main process building, where the creation of the feed will be happening. That's now reached its full height, it's 40 metres high and the roof line is now complete on it.

"That was the primary building to get finished. Because it's got all that activity happening within it, there's still a lot of work to be done in terms of installing all the equipment. All the mixing of ingredients, grinding, extrusion and then drying is all happening within that building.

"It's a very complex building, whereas all of the other structures around it are primarily for storage, so they're much simpler buildings to create. That is the reason why we started with the process building."

The photograph also shows storage silos emerging. "One of them is nearly at full height, the silver silo, off towards the back of the process building, and there is another one starting to emerge as well," said Read. "That is where the solid raw materials are stored. In total there'll be 15 of those."

Temporary pier

The slightly smaller dark grey silos at the front of the picture are for liquid raw materials.

"On the pier preparations are under way to begin the piling, which is necessary to carry out the slight extension of the pier, then bring it up to the right level to install all the conveyors that are required for moving raw materials in or finished feed out," explained Read.

"You can also see the temporary pier in front of the main pier, which has been put in just to enable the bringing to shore of the dredge material, because the depth of the water isn't sufficient for us to have the large vessels that we need to bring in the raw materials."

Reclaiming land

He said some of the dredged material - "a very good, clean gravel" - would be used on site, with the rest later sold as aggregate.

"There are 100,000 cubic metres of material to be dredged," said Read. "A lot of that we're using within the build itself, where we are extending out areas for increasing the space at the pier, and also where we are going to be putting the LNG storage stanks. We are reclaiming some land there."

"Things are moving forward very well," concluded Read. "We may well see a couple of days where we are affected by wind, which affects crane lifts and things like that, but we are trying to maintain a working pattern on site whereby there's plenty of stuff that can be done in terms of preparations at ground level if we can't so the lifting."

The plant will produce fish feed to supply Marine Harvest’s salmon farms across the western Highlands and islands of Scotland, as well as Ireland, Norway and the Faroe Islands.

The plant, which will employ 55 people, is due to be completed in autumn 2018.