Technology makes fish waste worth recycling

A deal signed this week could pave the way for on-land fish-farm waste to become an asset for the industry.

Blue Ocean Technology has inked a long-term agreement with water treatment solution provider Sorbwater Technology, which has developed a suite of completely biodegradable solutions for industrial high-performance water treatment applications.

Emissions reduced

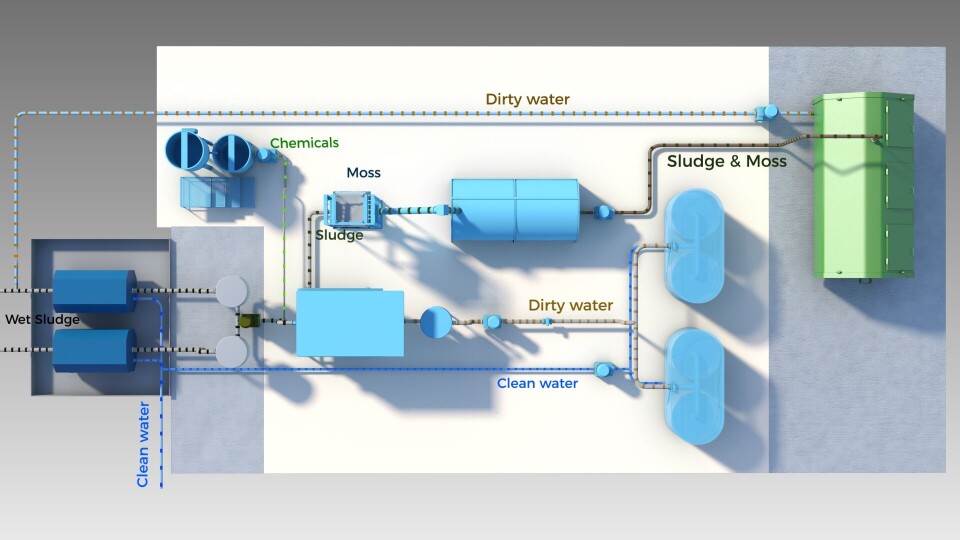

Through using the Sorbwater technology, utilising natural alginates, total particle emissions from aquaculture facilities are significantly reduced. Used in combination with Blue Ocean Technology’s organic moss filter, the combined heavy metal and particle content in the sludge is reduced by up to 90 per cent, allowing the phosphorus-rich aquaculture biomass waste (waste feed and excrement) to be transformed to fertiliser, or used to create bio-gas.

A version of the system is already used at Marine Harvest's Kvingo hatchery in Norway, where the more efficient waste disposal means it releases clean water into the sea and has enabled regulators to increase the amount of feed the hatchery is allowed to use to 850 tonnes per year.

Plates capture sludge

Floating solids in waste water are captured by Sorbwater's green flocculation chemical - Sorbfloc - and other filters. The waste water is filtered through lamella plates and then through a special type of dried peat moss imported from Canada. Blue Ocean Technology chief executive Jan Henning Legreid said the moss took 30 days to absorb water, compared to 24 hours for other mosses, a quality that benefited the process.

He added that use of the lamella plates to capture much of the sludge meant the moss only needed to be changed every fourth week, rather than twice a week.

Bigger biomass

Legreid said: "Aquaculture and fish farming are increasingly vital industries for Norway, indeed the world, moving forward. We are extremely happy to be working with Sorbwater Technology in such an exciting area.

“Our technologies and know-how combined truly shows that green solutions can be profitable solutions. And in addition to turning waste into a resource, it enables production of bigger biomass – as the restricting factor tends to be the waste emission quota.”

Although based in Norway, Henning said his company had ambitions to promote the technology in Scotland, Canada and Chile.