Safe sushi from salmon

By Hilde Herland and Grete Lorentzen Hilde.herland@nofima.no

The sushi-trend has spread like a fire in dry grass from being something one consumed when visiting customers in Japan to being found in the fresh food counter in the closest food shop. “Everybody” is eating it; it is bought in restaurants, grocers and take-aways and the consumption is increasing. Figures from the Seafood Council show that sales of sushi increased by 25% between 2010 and 2011 and by 28% between 2011 and 2012. And in a leading role we find Norwegian salmon, both as thinly sliced sashimi, in maki and on top of nigiri.

When food is consumed raw, one can potentially ingest bacteria that can cause problems for the consumers. One of the challenges in manufacturing companies is the pathogenic bacterium Listeria monocytogenes (hereafter referred to as Listeria). This has been described in Norsk Fiskeoppdrett (Fishfarming Expert) nr. 8 earlier this year. Listeria is a relatively tolerant bacterium that grows at refrigeration temperatures, and it can be a problem since it can stick to surfaces, such as conveyors and other production equipment. Once it is stuck, it is often a problem to remove Listeria with regular washing.

Production conditions Good quality is the core of processing salmon that will be used for “Ready to eat” products such as sushi and sashimi. Since the fish should not be heat treated before consumption, it is necessary that the hygienic quality in particular is extremely good, so there is no risk that the consumer gets sick. This implies a greater focus on quality throughout the entire process from live fish through slaughter and processing until the product gets consumed.

Salmon that will be consumed raw at the end of the production chain should be fish of good quality before slaughter, not so-called loser fish. The Veterinary Institute has found roundworms (nematodes) in both fish meat and entrails of loser fish. These are parasites that can cause disease in consumers. There was no evidence of nematodes in salmon from the same plant that was classified for human consumption; this underlines the importance of using good quality fish for “Ready-to-eat” products.

Furthermore, throughout the production line, it is particularly important to focus on hygiene, both personal hygiene and production hygiene. It is important for everybody that is involved in the production to thoroughly understand that the final product shall not be heat treated before consumption and possible consequences of poor personal hygiene. There have been instances where failing control and poor hygiene in facilities that process ingredients for sushi have been the cause of outbreaks of salmonellosis. Last year there was an outbreak that affected 400 people across 27 states in the United States. The bacterium was detected in tuna used in maki which was processed at an Indian plant. That plant had very inadequate control procedures.

A final issue one should focus on to preserve salmon quality and to inhibit the growth of undesirable bacteria as much as possible is temperature. An unbroken cold chain is a “must” for preserving fish in its highest quality. Low temperatures will inhibit the growth of disadvantageous bacteria, i.e. the growth of bacteria that cause bad smell and inhibit taste. As mentioned previously, the pathogenic bacterium Listeria grows at refrigeration temperatures, but growth is temperature dependent and is slower at lower temperatures.

Shelf life of sushi and sashimi As mentioned previously, it is no longer necessary to reserve a table at an exclusive restaurant to eat sushi, for many people it is possible to take it home with them along with other food from the grocery store. What about the shelf life of small pieces of fish? When salmon is stored gutted and with skin, it takes time for the degrading bacteria to penetrate the flesh and destroy it. However, if you store a fillet in the same way, the degradation proceeds much faster, because the bacteria have direct access to the meat, they do not have to work through skin and membranes. If the fillet in addition gets cut into pieces, the distance to the center of each piece is reduced even further (ratio between surface and volume increases) and it will take even less time before the bacteria have spread throughout the whole piece. In addition, a larger part of the meat is exposed to air, so that the rancidity process will also be faster. And the shelf life will be reduced even further. What about sushi and sashimi? Here we are, after all, talking about very small pieces of fish.

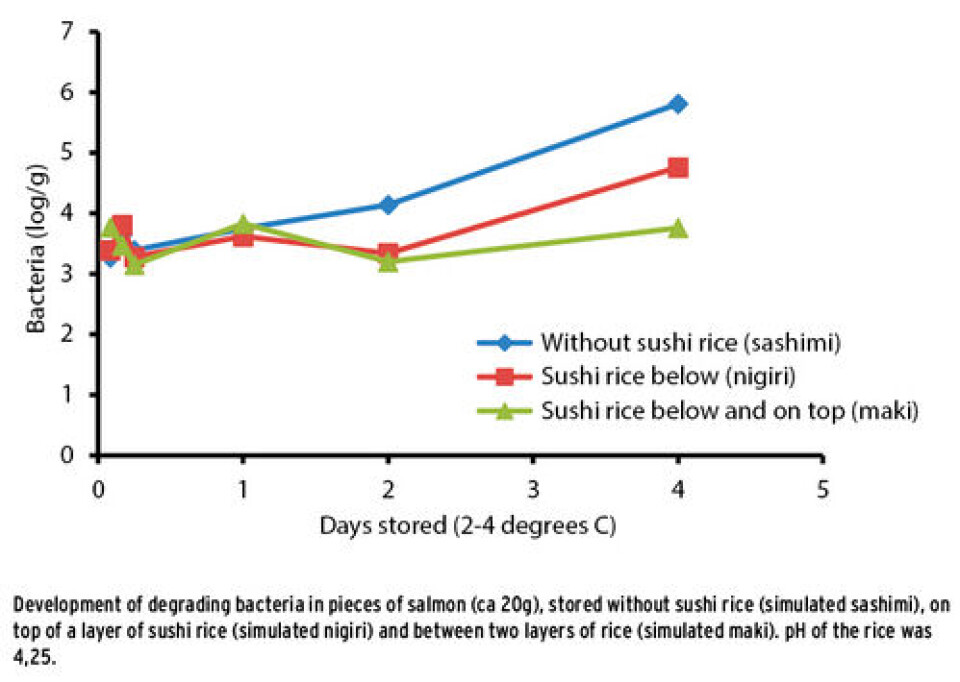

The development of degrading bacteria is influenced by the sushi rice (Figure 1). Sushi rice is rice mixed with vinegar and spices with an optimal pH of 4.2 to 4.6. The typical shelf life of packs of sushi is usually 2-3 days, during which time the fish in contact with rice will not be prone to bacterial growth beyond that which was in the fish from the production process. This is due to the acidity of the rice, which contributes to the natural inhibition of bacterial growth.

But when bacterial growth is so slow, can the shelf life of tray-packed sushi be increased? In theory, yes, but there is sensory element to be taken into account. Storage of sushi rice is actually a challenge as at refrigerator temperatures it usually gets a very hard consistency. By adding extra vinegar and some other additives, one can ensure that the rice remains humid for a while, but anything more than 2-3 days is unrealistic. And then only if the rice has a sufficiently low pH and is stored in a cool place, because rice can also carry unwanted components (like the pathogenic bacterium Bacillus cereus) that may develop during storage.

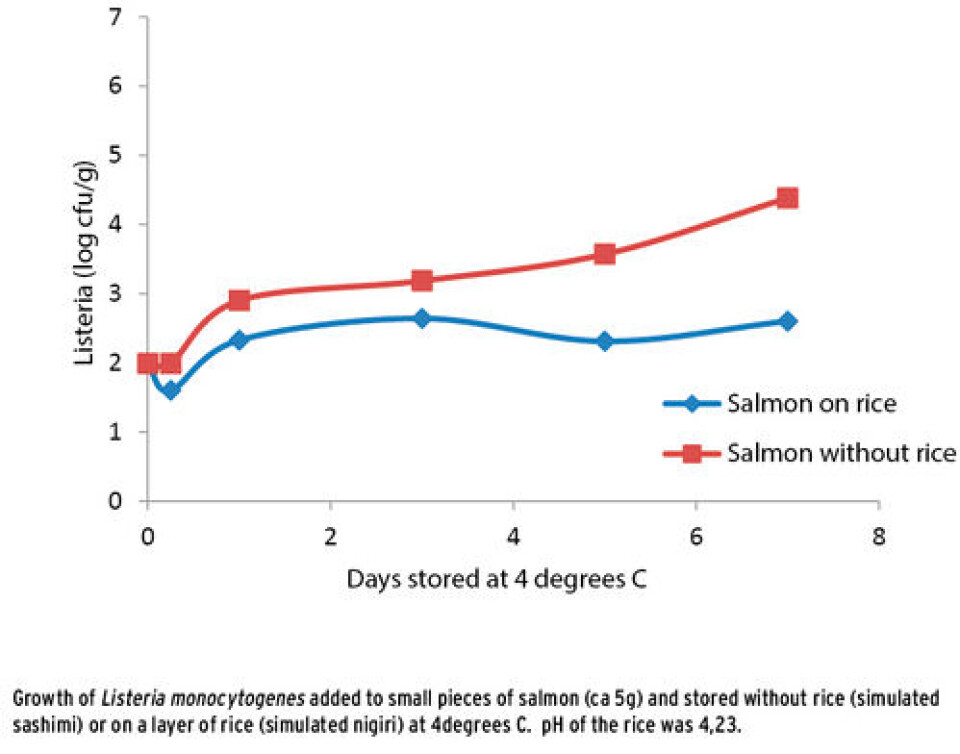

Growth of Listeria monocytogenes in sushi and sashimi As regards pH tolerance, it has been demonstrated in scientific studies that Listeria have different tolerances for different acids, and acetic acid is one that can affect the growth of Listeria monocytogenes. Comparison of the growth of Listeria in small pieces of salmon demonstrated that Listeria was affected by the vinegar in the sushi rice (Figure 2).

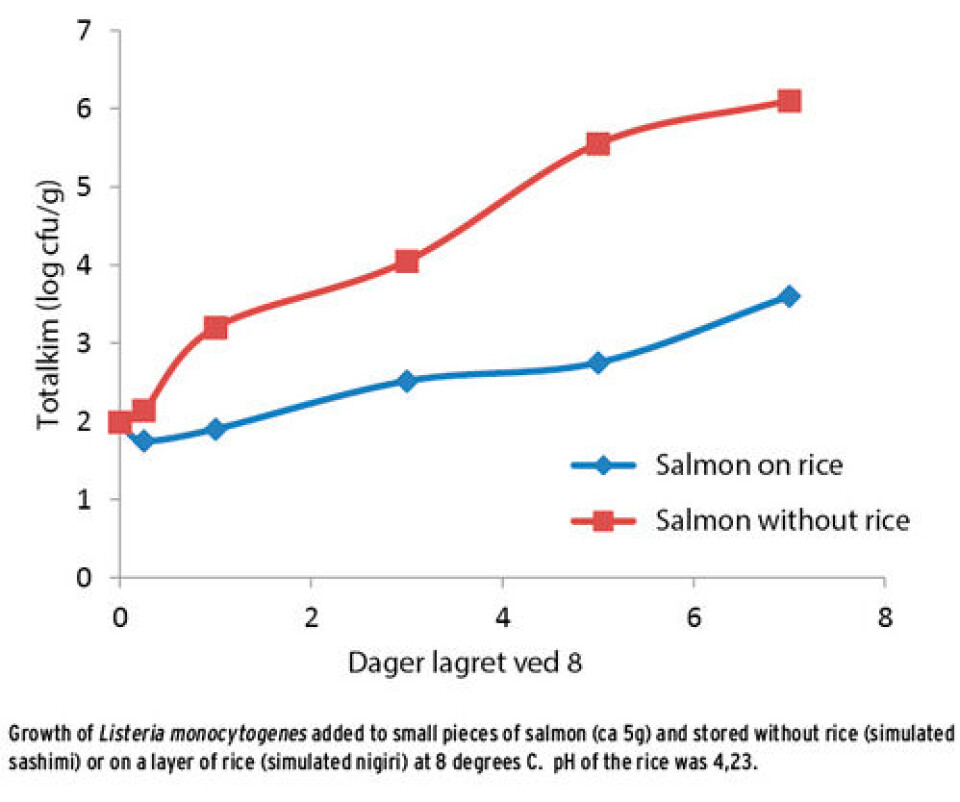

Growth of Listeria was also greatly inhibited by storage of samples at higher temperatures, 8 °C (Figure 3). This shows that if Listeria is present in pieces of fish which are in contact with the sushi rice, then growth is inhibited within the normal shelf life of tray packaged sushi. In addition, the sushi rice could counteract the effect of elevated temperatures that may occur during breaks in the cooling chain. But also here one should remember that the bacteria are only inhibited and the minimum level of bacteria that were there from the start will continue to be present.

Where, then, is the problem? Salmon of good quality is an excellent starting point for a lovely sushi meal, whether it is at a restaurant or bought in a shop. Shelf life is not a challenge for these dishes, due to a positive effect of the low pH of the sushi rice. But it is important to remember that sushi rice only inhibits bacterial growth, it does not kill bacteria, which means that it is the quality of the raw material that is essential. Quality of the raw material is affected by the slaughter process, cleaning and production hygiene and whether the cooling chain is unbroken. It is important to remind the consumer that when sushi is purchased, it is your responsibility to keep it at low temperature until it is eaten. At home in the kitchen is the personal hygiene and routines for handling and preparation that determine the final quality of the sushi. Bon appétit!