New aeration system for aquaculture

Norway: Suboptimal oxygen conditions are experienced periodically in many fish and shrimp farms, causing increased feed conversion rates and higher production costs. A new air diffuser system is now under development to improve oxygen conditions in aquaculture farms.

Oxygen deficiency can constitute a challenge in aquaculture, especially when water temperatures are high. This challenge manifests itself in decreased appetites, low-level feed utilisation, slow growth rates, increased stress among the farmed stock, and higher production costs. The factors resulting in oxygen deficiency typically coincide during summer and early autumn – at a time when the stocking densities are normally quite high. This can result in prolonged periods with low oxygen levels, making it necessary for the farmer to alter husbandry practices in order to reduce the need for oxygen.

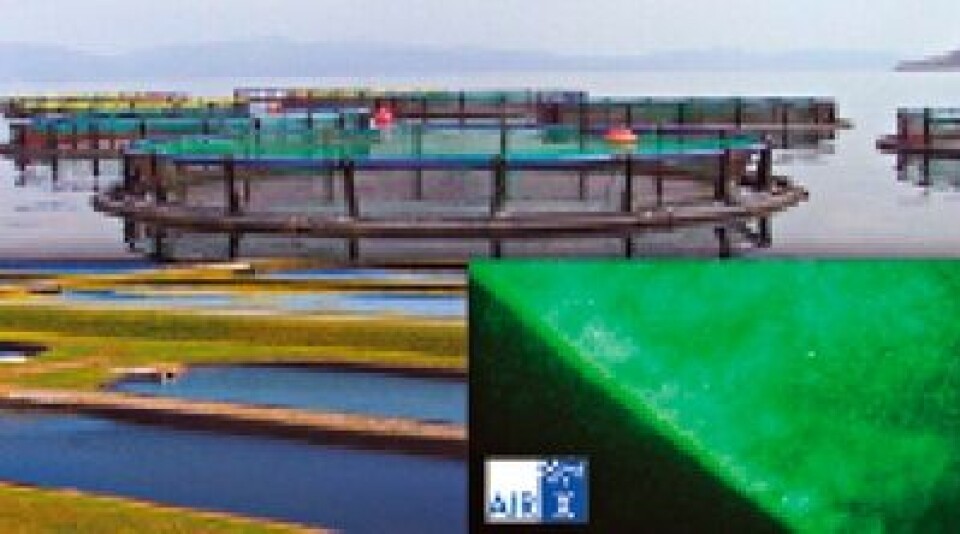

EU’s recently launched AirX project will over the next two years develop and test a new technology that uses air to control dissolved oxygen levels in aquaculture. The concept, which has already been patented, is designed for use in large farming facilities, including earth ponds, sea cages, tanks and raceways.

Introducing air diffusers for large rearing units Currently, cage farmers rely singularly on the ability of the sea current to replace oxygen consumed by farmed fish. In earth ponds, on the other hand, aeration devices such as paddle wheels and air jets are commonly used. – “The aerators used in ponds today have high cost per kg of oxygen that is transferred to the water. The situation regarding sea cages is that there is no suitable aerator currently on the market. With this project we will provide new technology that can be used cost efficiently also in large rearing units such as ponds and fish cages. We therefore consider the AirX aeration system to represent an important innovation for the aquaculture sector upon its market introduction in just a few years time”, comments Martin Gausen, Manager of the Norwegian company Oxsea Vision.

Improved feed conversion and production capacity Initial tests have shown that AirX is able to add oxygen in an efficient and homogenous manner throughout the water volume. The diffusers system is also designed to direct diffusion towards areas in the rearing unit where oxygenation is mostly needed.

– “The main benefits from using AirX will be that better feed conversion and growth rate of stock can be efficiently achieved even in large rearing units such as ponds and cages”, according to Mr. Gausen. He further explains that current EU-regulations for organic aquaculture prohibit the use of pure oxygen under routine operations. –“AirX uses air as the oxygen source rather than pure oxygen. We therefore expect the new diffuser technology to also prove itself as a viable alternative to achieving increased production capacity in organic aquaculture farms”, says Mr. Gausen.

The majority of the technical development takes place in Norway in collaboration with Teknologisk Institutt (TI), while verification tests are performed in liaison with companies in Greece, Portugal, and Italy. Mr. Gausen encourages those seeking more information to contact TI.