Chile’s high-energy site cages ready for first fish

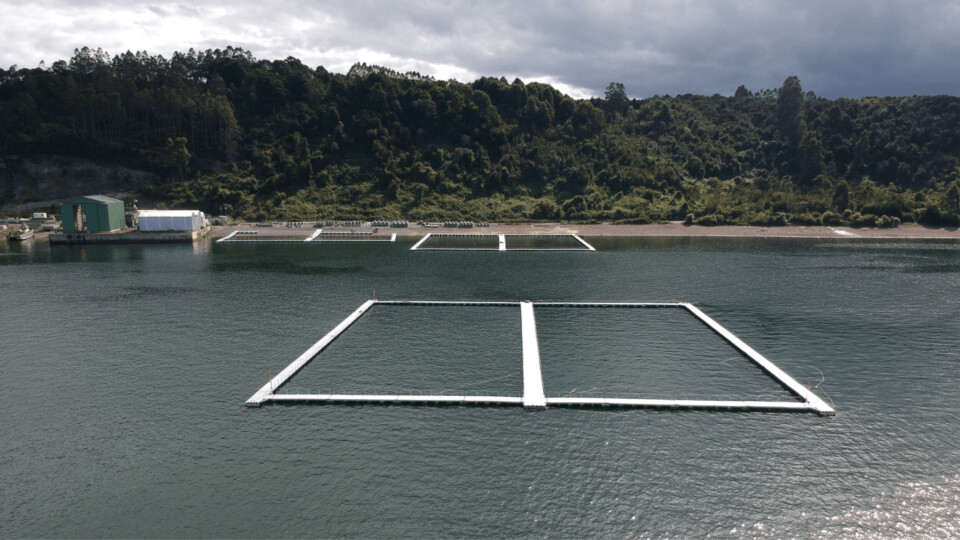

Two extra-large salmon cages designed for use in a high-energy environment have been transferred from a Chilean shipyard to a test site and will be stocked with fish at the end of the month.

The 80-metre x 80-metre cages, on a site operated by salmon and trout producer Marine Farm, are production-scale prototypes for a project run by the Technological Consortium for Oceanic Aquaculture, which is backed by a number of the country’s salmonid producers.

The site in the south of Chaitén, in Corcovado, Los Lagos, is an area that is characterised by currents in the range of 2.4 knots and waves in the range of 3-5 metres.

Biggest cages in Chile

The cages, which are the biggest in Chile, will each be stocked with 400,000 fish.

The design and construction were carried out by the company Walbusch.

Characteristics include structural robustness and articulation, damping and pivoting components that enable the cages to withstand high marine energy, a special mooring system to maintain the volume of the cultivation net, and a central aisle that provides safer access for workers.

Remote monitoring

“From the concept of anchoring, the cage, support of both the predator and fish nets, it is all new, there has been intensive innovation,” Walbush executive director Walter Buschmann told Fish Farming Expert’s Chilean sister site, Salmon Expert.

Once the cages are stocked, one of the most important processes will be to implement an experimental design that allows recording and validating of the operation of the technology.

“A relevant aspect that addresses the project is that of remote and real-time monitoring of different variables such as acceleration, traction and compression that affects the productive infrastructure, environmental indicators, as well as productive indicators: fish growth, food, everything will be automated,” Buschmann said.

More oxygen

The executive told Salmon Expert that the main challenge at this stage “is to continue innovating as soon as we see the results of how the whole cultivation process is developed”.

He added: “The design ensures greater replacement of water and oxygenation than traditional cages. In addition, we hope that the crop cycle takes place in a shorter period of fattening. We are aiming at that: that there is better feed conversion and that the sanitary process is better as well.”

Walbusch general maager, Julio Muñoz, said that the innovation seeks to “mark a before and after in the industry, where this is the first cage that will be installed in such extreme conditions of currents, waves”.

“Our bet is to show the industry that different things can be done, that can be installed in sectors that are much more complex, and that technology exists today.”

Claudio Pavez, director of the Technological Consortium for Oceanic Aquaculture, said the Walbusch cages were being developed using a systematic methodology of research and development and innovation incorporating an important number of experts in design, ship engineering, biology and fish production.