Lumpfish on the menu

Taking place in collaboration with the North Atlantic Fisheries College (NAFC) in Scalloway, under the watchful eye of project supervisor Jennifer Murphy-O’Connor, the ambitious project is making headway at the moment and the first fish are due to be released into smolt cages before the end of the year. Here Jennifer explains the aims of the project and the challenges she has encountered when rearing the lumpfish to date.

Has Hjaltland tried using lumpfish as cleaner fish before? Yes the last project, which was also a collaborative effort with the NAFC, took place in 2012-2013, but although sea lice were found in the stomachs of the lumpfish, there was not a statistically significant difference in sea lice numbers between the lumpsucker stocked pens and the controls in all weeks of the project. This was largely because we still had a lot to learn about lumpsucker behaviour and husbandry. How is this project likely to differ? The biggest difference is that we have a much greater understanding of the biology and requirements of lumpsuckers and we will have a dedicated lumpfish technicians and supervisor (me). This will allow us to focus more on the important details to ensure the lumpsuckers are effective as cleanerfish. For example we will need to ensure that the nets are kept extra clean – otherwise the lumpfish will feed off the fouling organisms that live on the nets, such as skeleton shrimps (Caprella sp.)and be less likely to feed on lice. I’ll also be able to ensure weekly sea lice counts in the pens, examine any sick lumpsuckers and undertake regular stomach content analysis to see what the lumpfish are eating – including the number of lice.

Another big change is that we’ll be introducing the lumpfish into the salmon pens when they’re much smaller. Last time they were introduced at 100g, but we think it’s important for the two species to build a relationship that will last for the whole cycle and we will ideally introduce the cleaner fish as soon as the smolts go to sea – at this stage the lumpfish will be 15-20g.

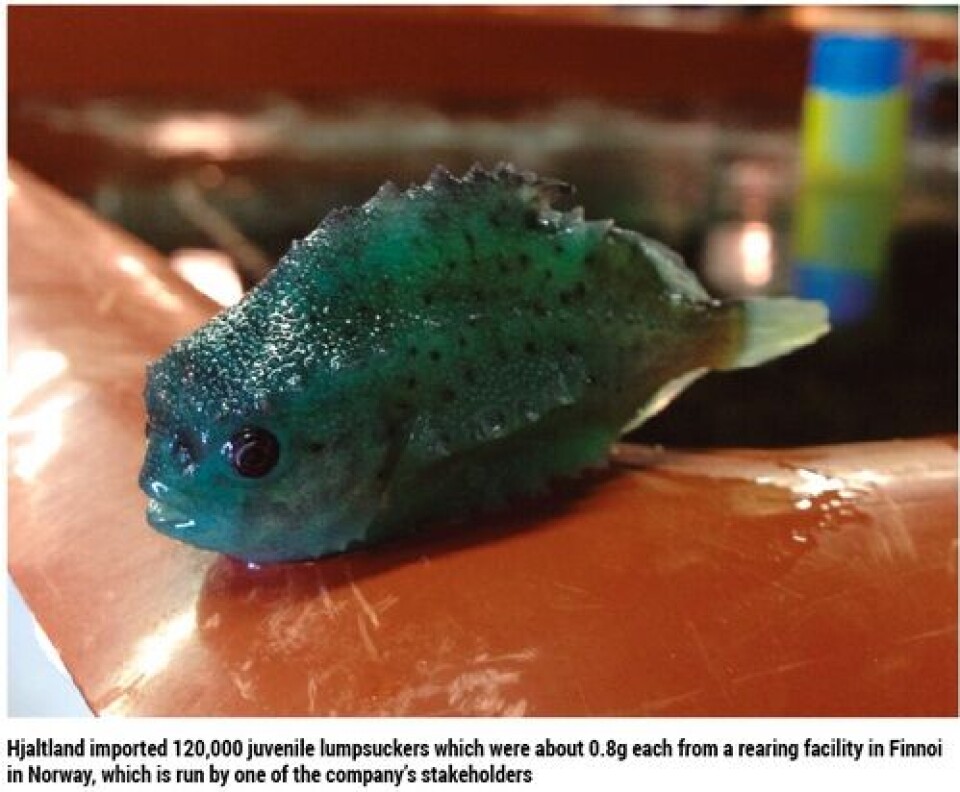

Do you rear the lumpsuckers from eggs in Shetland or are the early stages done elsewhere? We imported 120,000 juvenile lumpfish which were about 0.8g each from a rearing facility in Finnoi in Norway, which is run by one of the company’s stakeholders. The lumpsuckers are being held in quarantine for three months in the NAFC prior to stocking in the sea to ensure best possible biosecurity.

What was your previous experience in aquaculture and is this an exciting project to be a part of? I graduated with a degree in Marine Biology from Stirling University and became interested in the aquaculture industry while doing my dissertation on the interactions between wild and farmed salmon. When I graduated I became a graduate trainee for Hjaltland’s farming operations in Shetland, which allowed me to concentrate on fish health and welfare. When this programme was set up I leapt at the opportunity and it has been a very exciting project to be a part of so far, although it’s also been quite hard work.

What’s the projected cost of the project? It is expensive and the cost will be a six figure sum but if it helps to reduce the number of treatments we have to give our salmon and improves the overall sustainability of salmon farming then it will be worth every penny.

How many people are involved? There are two staff at the NAFC, myself and my assistant directly working with the fish at present but the number of people involved in the project will vary over time.

What are the major health issues you’ve encountered working with lumpfish? The lumpfish came from Norway to Shetland by wellboat and the transportation can be stressful so we needed to pay careful attention to them for the first week in the hatchery here in Shetland. We also observed quite a lot of aggressive behaviour in the early stages at the hatchery – with the fish biting each other’s tails. We have managed to control this problem however by regularly grading the fish to make sure the large lumpsuckers do not bully the small ones. They have also become less aggressive as they’ve grown and seem to stop biting each other when they’re over 15 grams. Our next challenge will be vaccinating the lumpfish against vibriosis, but we have a team of experienced people coming over from Norway to help with this.

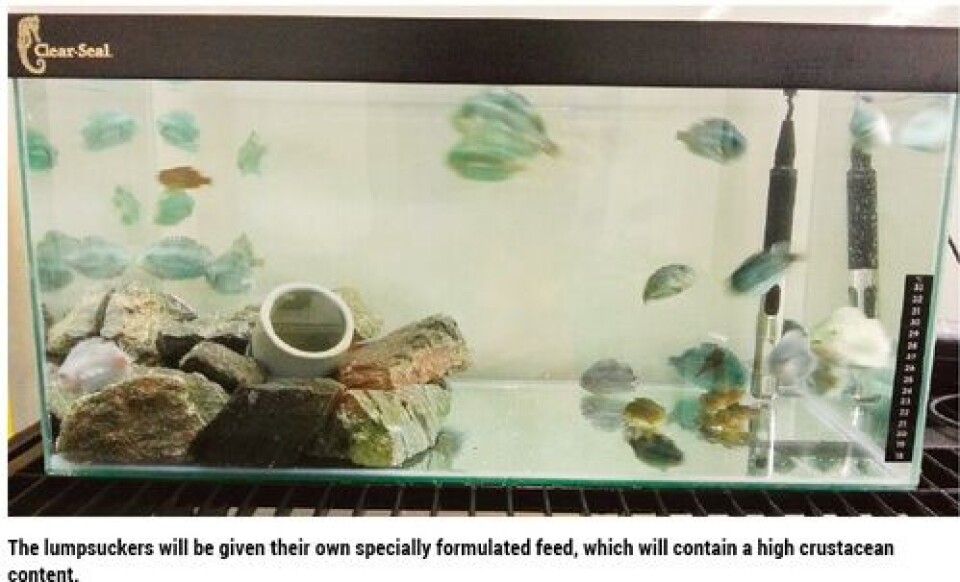

What feed formulas have you been using? We’ve started off using a Japanese formula called Otohime, which contains ingredients such as crab, squid and krill and smells just like crabsticks. It’s been very popular – it has a very slow sinking rate which suits the lumpfish, as they like to grab the pellets from the surface, although they’ll also feed in the water column.

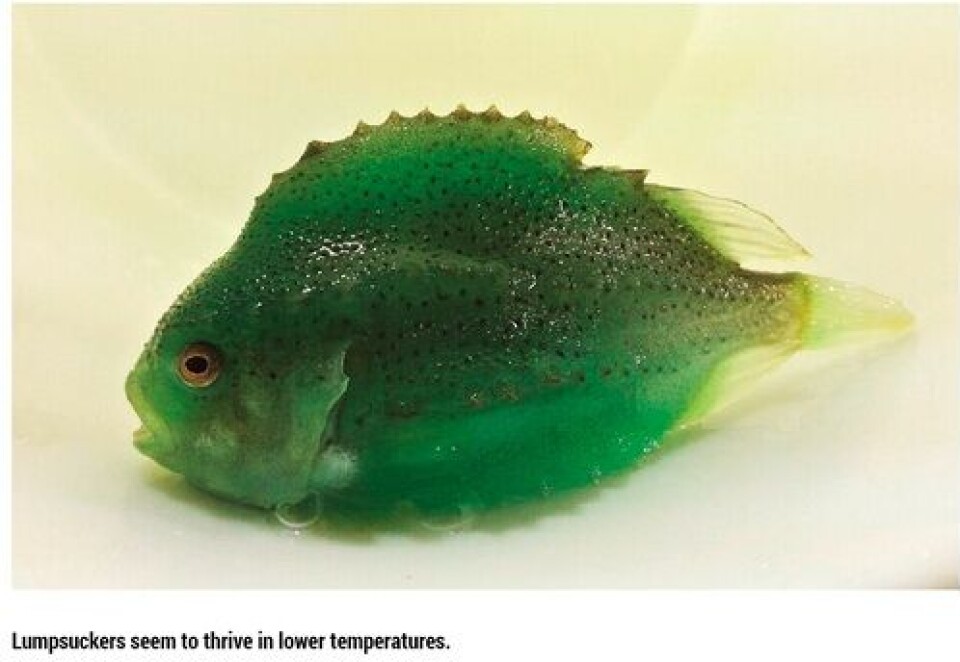

Do you think they’re better suited to Shetland’s salmon farming industry than other species of cleaner fish such as wrasse? Shetland is quite a wild environment and the sea water temperatures can fall quite steeply in winter, to a level below which wrasse, for example, do not function optimally. Lumpfish, on the other hand, are known to feed all year round – they seem to thrive at lower temperatures. Another advantage is that lumpsuckers appear to be less susceptible to viral diseases when compared to other cleaner fish. What’s more, the lumpfish are much quicker and easier to grow than wrasse – we can grow them from egg to a size they’re ready to release into salmon cages in less than six months, whereas wrasse typically need to be reared for one and a half years before they’re ready to be released.

What sort of system is used at the NAFC’s Scalloway Marine Hatchery? As we’re situated on the coast we use a flow-through system with the sea water passing through a 25 micron drum filter on the way in and a UV filter on the way out. We initially housed the lumpfish in 8 tanks with a three cubic metre capacity, and have then transferred them to 6 tanks, each with a 21 cubic metre capacity, as they’ve grown – they put on 3% of their body weight each day and can double in size in just two weeks, so they need to be graded regularly.

What is the planned ratio of lumpsuckers to salmon in the sea cages? We plan on stocking them at 7-10% of the number of salmon in the pen.

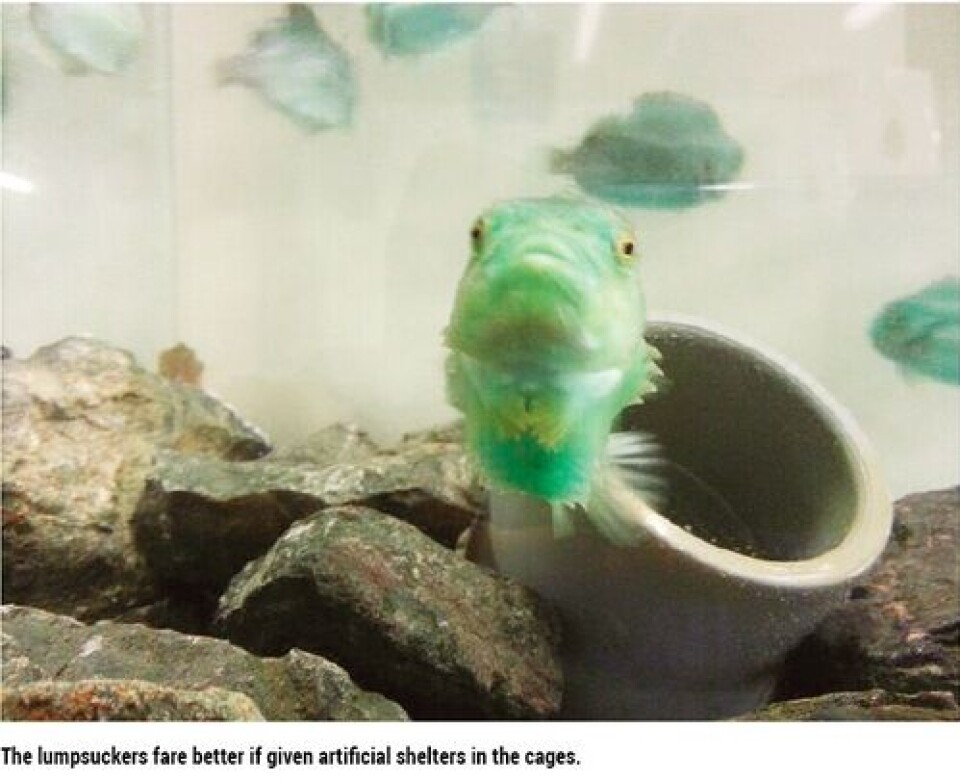

What are the likely challenges facing the lumpfish when at sea? We will have to build shelters for the lumpfish and also feed them their own specially formulated feed, which will contain a high crustacean content.

What will happen to the lumpfish when the salmon are harvested – is there a potential to reuse them in other cages or can they be processed for anything? The lumpfish will unfortunately be humanely culled when the salmon are harvested. The risk of disease transmission means that it is unlikely that lumpsuckers can be reused.

Do you think that cleaner fish will significantly reduce the use of other lice treatments? I’m realistic enough to realise that the lumpfish are unlikely to cure the lice problem completely, but as long as they can help to decrease the use of lice treatments and help to keep the lice burden at or below our goal of 0.1 adult females per salmon then it will achieve our objectives.

Is there a capacity to increase the scale of the project if it proves to be a success? I’m sure if the project is a success then we and other salmon farmers will be looking for more lumpsuckers in future.