Pump maker joins fight against lice in sheltered sites

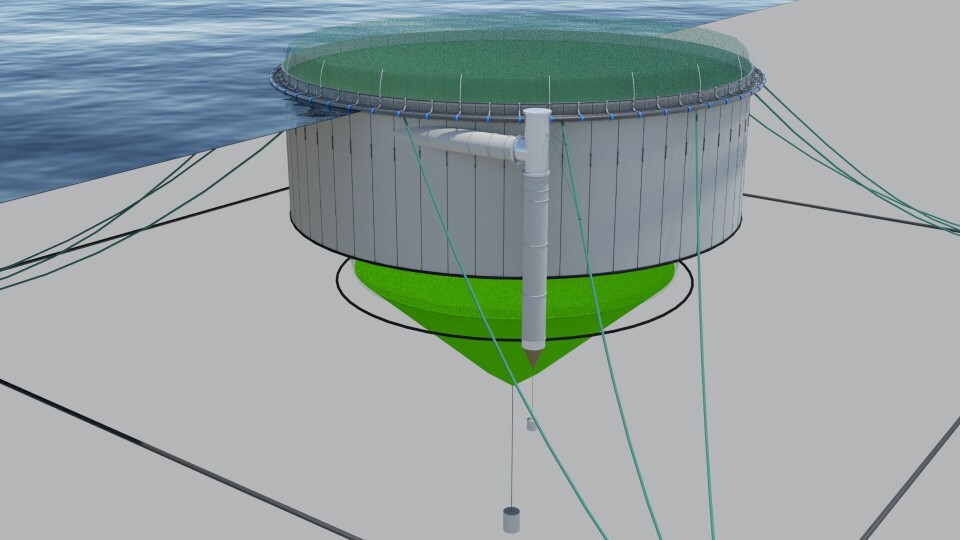

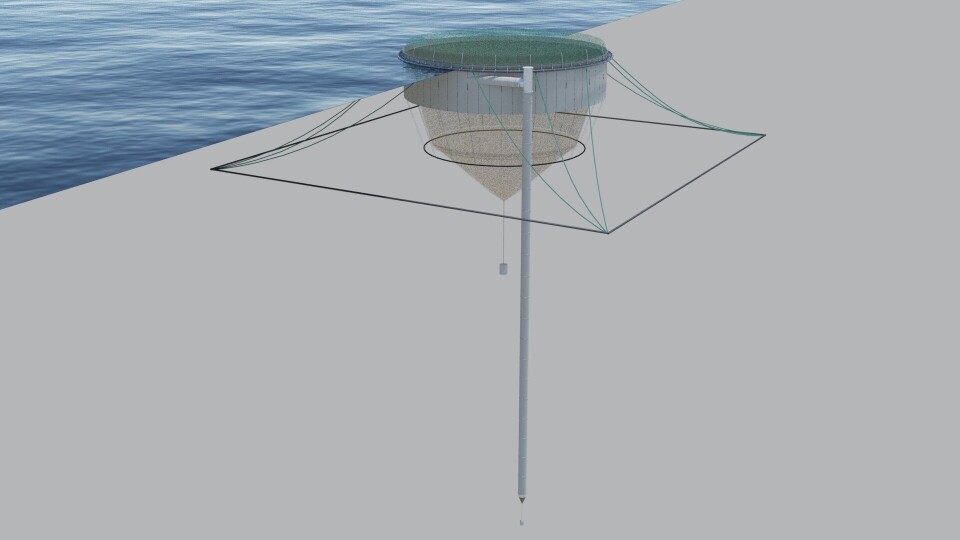

Lice-skirt manufacturer Norwegian Weather Protection (NWP) is combining its expertise with pump-maker Framo to provide a system that keeps lice out of salmon cages without the negative effect of reducing water exchange in sheltered sites.

In a press release, the companies write that the system can be installed on existing cages, and that it may be tested in the autumn.

“We want to bring fresh water from deep under the lice layer. This way we can create good circulation when lice skirts are installed in low-power locations. The pumps blow in water and provide a replacement in the cage,” says director Oddbjørn Jacobsen, of Framo Innovation.

The new innovation department of Framo AS will use its core competence of pump technology to assist fish farmers. To prevent lice being pumped into the cage, water can be pumped up from variable water depths up to 100 metres.

“Lice skirts prevent lice, but especially on calm, hot days, they also restrict new water into the cage. With submersible pumps we can go so far down that we can ensure circulation and proper oxygen content in the water,” Jacobsen points out.

Contributing to development

Framo and NWP are working with individual fish farmers, and aim to test the system at a Bremnes Seashore plant in the autumn.

“Bremnes Seashore is an innovative aquaculture producer that wishes to engage in projects that develop nutrition. We are looking forward to contributing to the development of new technology that prevents lice,” said CEO Einar Eide.

Norwegian Weather Protection is a long-standing lice skirt producer and has been enjoying growth. Its products have recently been used successfully by Scottish Sea Farms.

Canvas closed cages

“With the industry’s lice challenges, we can see that canvas-based products can also be further developed into semi-closed and closed plants. Here, Framos technology fits perfectly,” says Arne Dalland, general manager of NWP.

The two suppliers are both based in the Bergen area, and make the point that they supply only Norwegian-made products. In February, NWP will move production from the two factories it uses now to new premises better suited to the large-scale sewing and fabric welding work it carries out.

“It gives us greater opportunity to produce large, heavy canvas constructions. It will be a unique opportunity to develop new products that give the aquaculture industry great benefits for better fish health and thus increase the growth and quality of the fish,” Dalland concludes.