Drum filter or disc filter? Experiences from RAS facilities and tests

One of the key treatment steps in recirculating aquaculture system plants is efficient and gentle particle removal. It is important to get the particles out as quickly as possible so that they are not degraded into finer particles or broken down by bacteria in the water. This addresses some of the differences between using a drum filter and a disc filter in a RAS context.

By Henrik Grundvig and Bjarte Landro, both NP Innovation Norway AS; Mikael Lundfelt, ML Vatten & Slam AB; and Nils-Åke Persson, NP Innovation AB.

Microscreens have been used for aquaculture for a long time. The drum filter, especially, is extensively applied both for inlet and effluent treatment in flow-through plants, and for particle removal internally in re-use and RAS plants.

Although the drum filter is one of the most widely used particle removal technologies in RAS today, there is another well-proven microscreen that may have advantages, especially in the RAS system of the future. This is the disc filter.

How drum filters and disc filters work

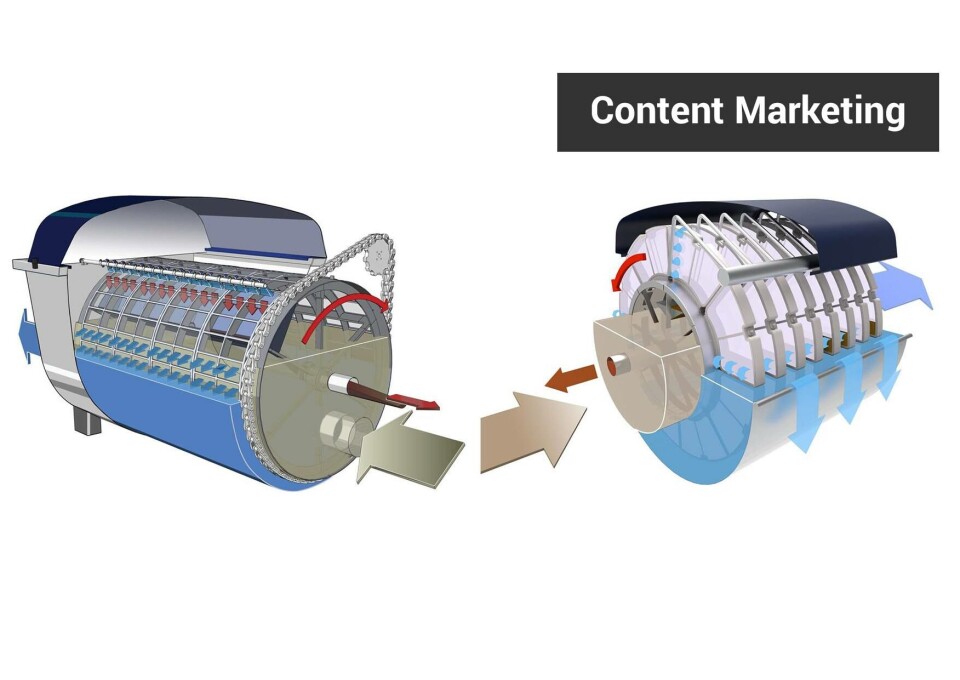

As the name indicates, the drum filter is built around a drum-shaped skeleton enclosed with external filter panels. The untreated water flows into the drum, and gravity drives the water through the filter panels and out of the drum (Figure 1a).

In the disc filter, the influent water also enters a central drum. The drum has a number of openings that distributes the water to the filter discs (Figure 1b). The disc segments are made up of several filter cassettes with filter cloth on both sides. This increases the filter area considerably. The water is filtered passively through the filter cloth in a similar manner as for the drum filter. However, the disc filter has a significantly larger filter area which provides a more efficient filtration, or alternatively a smaller footprint.

As particles accumulate on the filter cloth and the resistance increases, the water level inside the filter will rise with time. Common to both types of filters is that a backwash cycle is automatically initiated when the water level reaches a certain level.

The filter panels are then sprayed from the outside to clean the filter cloth. Reject water containing particles is collected in a long trough located inside the filter, along which it exits, e.g. to a collection tank for further sludge treatment.

Larger filter area in a smaller space

A disc filter has more than three times the filter area of a drum filter with a corresponding footprint. It is therefore possible to use much finer cloth in the disc filter and still ensure favourable overcapacity in relation to the filter area. This prevents the differential pressure from increasing too much over time as a result of fouling of the mesh. For example, it is possible to use 30 to 50-micron cloth instead of 60-micron which is widely used in drum filters.

In general, fewer and smaller units of disc filters will be needed when compared to drum filters. Being able to take up less space for filter installations can also have other positive economic aspects, for example by reducing the size of the building and the plant site.

Backwash water and energy consumption

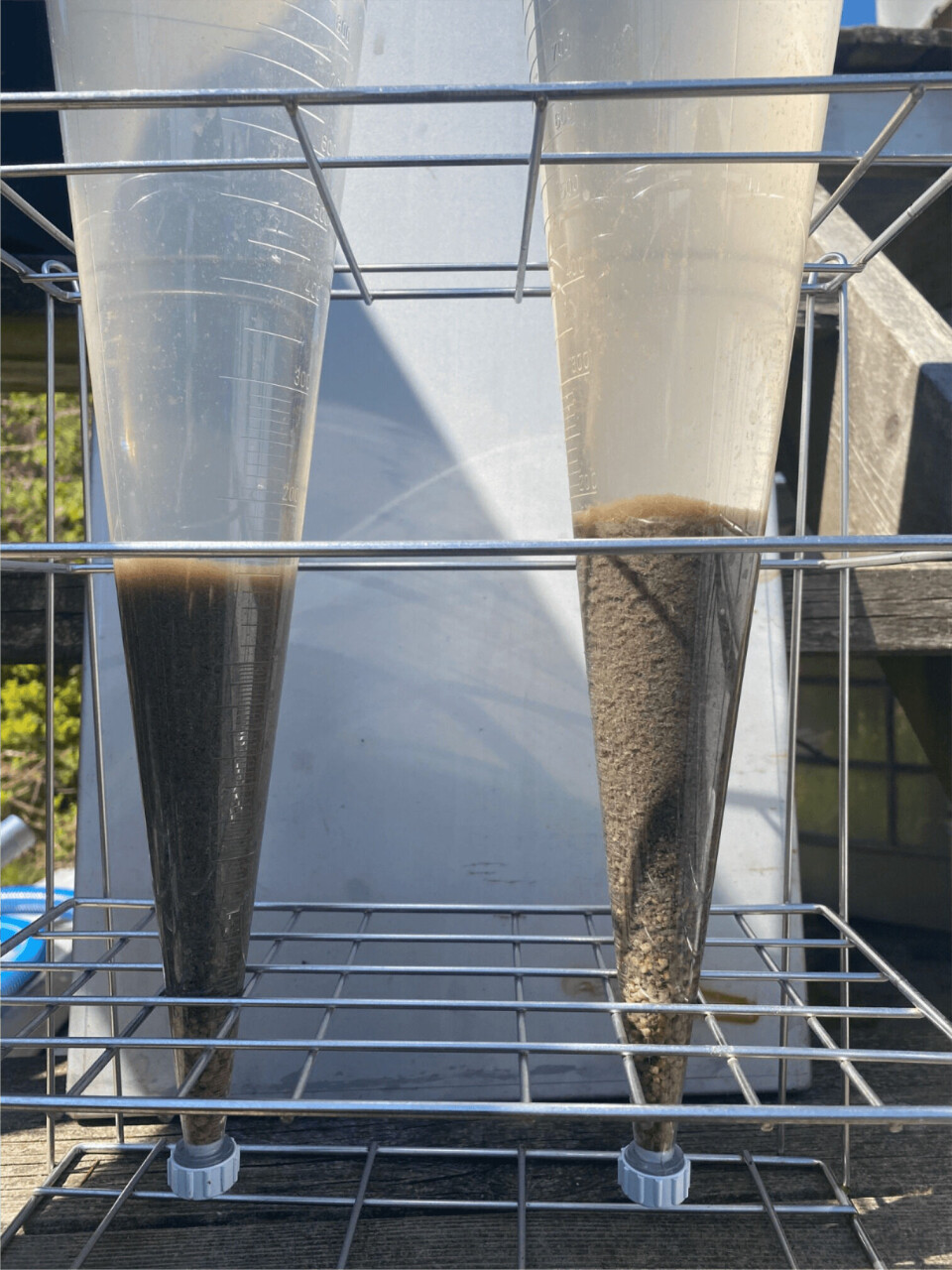

Tests with water from RAS modules at Vik Settefisk in western Norway (figure 2) have shown that a disc filter consumes 45% less backwash water than a drum filter while extracting the same amount of suspended matter.

The tests were performed in parallel with water from the same fish tank. The reject water was collected, and the sludge volume was measured after sedimentation. Following a proper mixing of the sediment, a sample was taken to measure the concentration of suspended solids (SS). The trial was repeated 10 times. The result showed that the SS concentration in this experiment was almost twice as high in the reject water from the disc filter compared to the drum filter.

So, what are the benefits of being able to minimise the amount of reject water beyond reducing the water consumption?

Firstly, the operating cost is reduced corresponding to the reduction of the backwash water. The energy consumption – which is mainly spent on pumping backwash water and rotating the drum – is therefore 45% lower in a disc filter than in a drum filter. Secondly, there will be less volume of sludge that must be stored and dewatered. This in turn can reduce the need to invest in sludge storage and dewatering equipment.

Rapid removal of large solids

In RAS, rapid particle removal is essential to maintain good water quality. The aim should be to remove the faeces that the fish produce as quickly as possible. This reduces the risk of large particles dissolving into finer particulate matter that is more difficult to remove from the system.

A disc filter is significantly more efficient at removing large particles, such as waste feed and feces, than a drum filter. A particularly good result has been achieved by fitting the filter cassettes with “collars” that help lifting out the solids. A test was performed to compare how quickly different filter panels and cassettes lifted out 100 ml of feed pellets with a diameter of 5 mm. As shown in figure 3, the disc filter cassette with collars is far more efficient at catching the pellets than the drum filter panels. We believe a similar effect would be observed if the pellets were to be replaced by large faeces, e.g. from post-smolt or adult fish.

The reject water from the drum filter also contains more dissolved suspended fine particulate matter than the disc filter. This is despite far less reject water being produced from a disc filter than from a drum filter. Figure 4 clearly shows that the clear phase of the disc filter reject water is the most transparent following sedimentation. This may have something to do with the disc filter having a larger filter area and that the particles are being less degraded and ground down than in a drum filter.

Optimise the load on the filters

In general, a larger filter area will provide a better filtration effect in all types of microscreens. Our recommendation is to avoid loading the filters so heavily that they are run more or less in continuous backwash, as this reduces the filtration effect and probably also increases water consumption. The filter is more effective at catching particles if the particulate matter has time to adhere properly to the filter cloth before the drum starts to rotate and backwash. For best results, we believe it is wise to size the filter with extra filter area. This also helps to avoid getting into trouble if a lot of fouling should eventually occur in the filter cloth.

In short, there can be many advantages using disc filters for particle removal in RAS systems.

To order NP Innovation Disc and Drum filters in the US, Mexico and Canada, contact Innovasea at https://www.innovasea.com/land-based-aquaculture/ras-equipment-supply/drum-filters/.