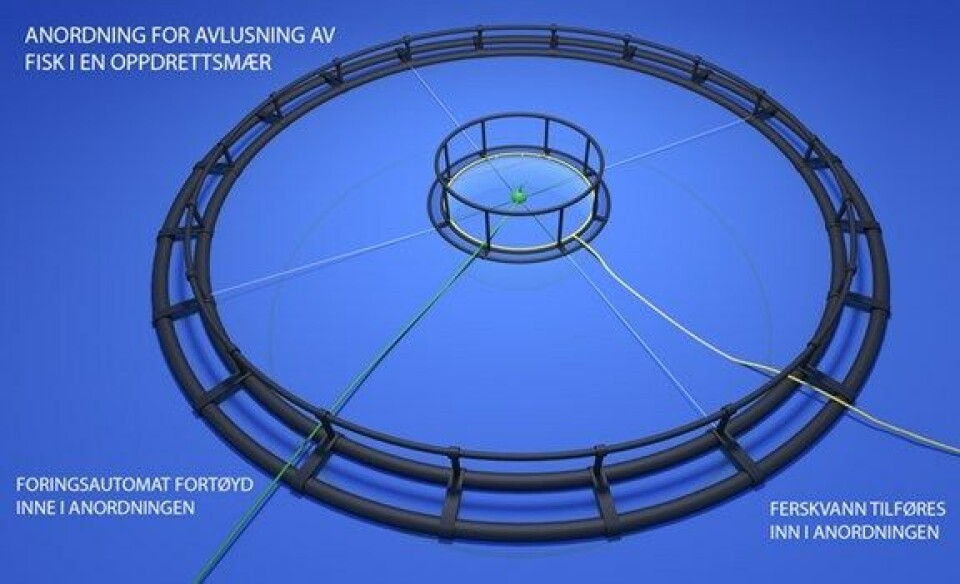

Novel freshwater treatment scheme

An innovative means of administering fresh water treatments for salmon, in order to reduce sea lice numbers, is the subject of an application for four development licences by Ballangen Sjøfarm.

The company applied in July for four such licences – which would allow for the production of 3120 tonnes of salmonids a year – for a project that exposes fish to low salinity water several times daily over long periods.

This is achieved by feeding the fish inside a cylinder within the cage that contains fresh water – thus allowing them to be treated without stress or risk of physical damage.

The technology optimizes the fish welfare and concern for the environment,” Ballangen’s general manager, Ottar Bakke, told kyst.no. “The solution we have ended up with combines the best possible animal welfare with the minimum amount of fresh water, while no pumping, moving or otherwise handling the fish is necessary.”

Fresh water must either be transported to the sites or produced on site by means of reverse osmosis and the method is designed to minimise these costs.

Evolution

The company has been awarded a patent for the design, which is valid until 2032 and should, Bakke hopes, prevent the idea from being exploited by other companies, although he is keen to sell the system to other operators, should it prove effective

“We know of other solutions similar to this, but ours is patented, so other parties cannot use it without entering into an agreement with us,” says Bakka.

“When we start up we expect overall technology costs to be hundreds of millions but when the technology is fully developed, it will be cheap to use for the industry,” he adds.

If approved, Ballangen Sjøfarm – which has 16 permanent employees and produces a total of 5,000 tonnes per year – will initially develop and operate the system on one of their six farms in Ofotfjorden in Nordland, before rolling it out to the other sites in phases.