New concept for closed RAS at sea is unveiled

Norwegian technology company Multigen Akva has developed a modular post-smolt and food fish facility. Its goal is to bring the industry back to sheltered coastal areas.

Multigen Akva from Vågan in Nordland was founded in 2022 by the entrepreneurs Kristoffer Høyning and Ole Marius Rostad. The company is now launching a recirculating aquaculture system (RAS) concept for closed sea farming. The goal is to re-use sheltered coastal areas that have previously been used, with the help of the company's RAS technology and a specially developed anchoring solution.

Joining the team is veterinarian and fish health expert Per Anton Sæther.

"The fish will be offered the same safe and good growing conditions regardless of whether the facility is located in Lofoten or in the Oslofjord, and it opens up [an option] for the production of multiple generations in one and the same area," Sæther tells Fish Farming Expert's Norwegian sister site, Kyst.no.

General manager Kristoffer Høyning has a background in both innovation and management in the aquaculture industry. He says Multigen's team have in-depth knowledge and experience in engineering and consulting with special expertise in RAS technology and project management.

New concept

Høyning tells Kyst.no that the development process has taken place over several years, where the team has emphasised the fish's biology and welfare by facilitating stable and controlled conditions.

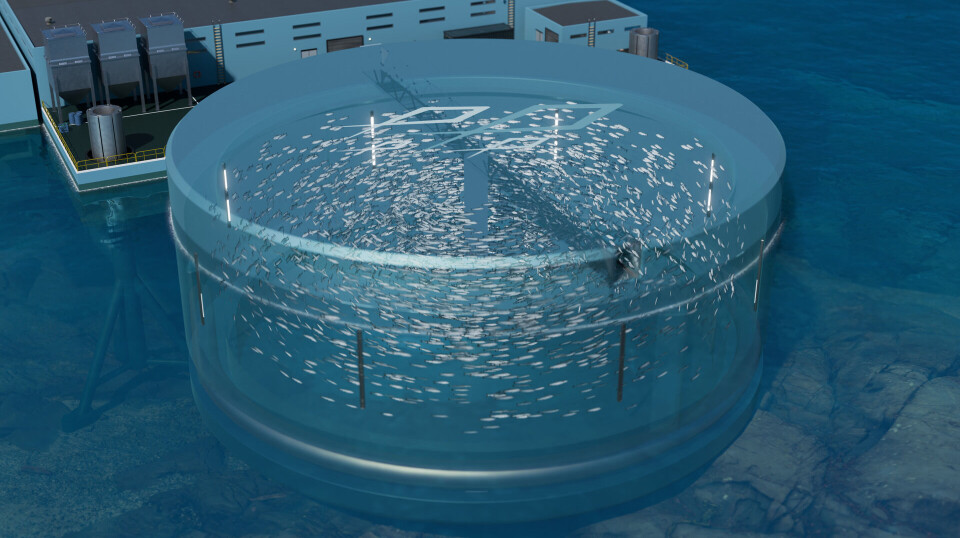

The closed facility is a floating RAS at sea using ultrafiltration on the incoming water, which Høyning claims has a documented effect on the removal of both viruses and bacteria.

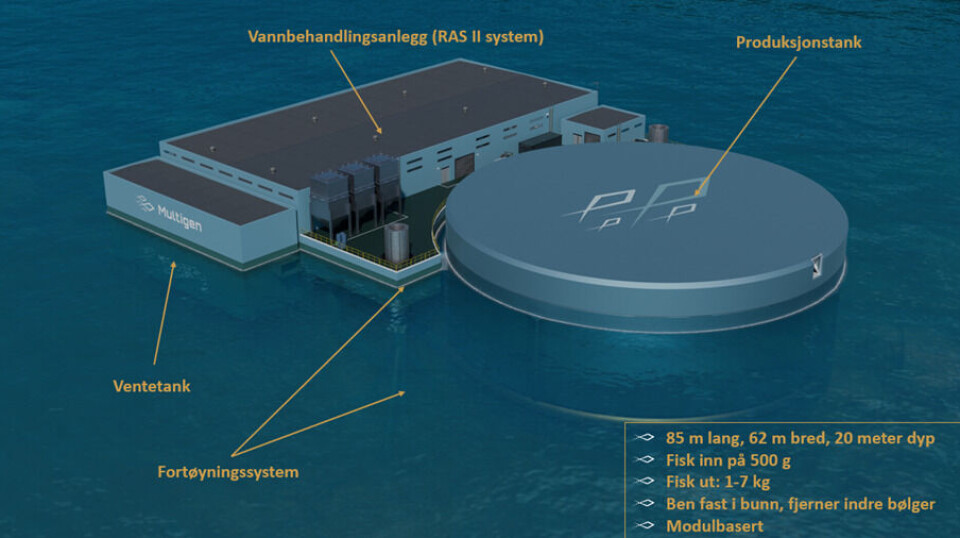

"The facility itself, consisting of the RAS float modules, production tank, and waiting cage, is scalable, so it can be connected to more facilities if desired, he explains.

Reduced land use

Høyning explains that the technology opens up the use of first-generation areas, where the aquaculture industry started, but which are now less attractive due to limited carrying capacity with traditional methods.

"These areas, which are often well sheltered with depths of 7-45 metres, have enormous potential for sustainable aquaculture," he says.

The modules the company has developed are compact and can scale production depending on the size and needs of the location.

Høyning also believes this enables high utilisation of area. Space required is less than 5% compared to open cages and 20-30% compared to land-based facilities.

The facility will also be well anchored to the seabed.

"Our anchoring solution is specially developed to prevent the formation of internal waves in the structures and provide increased stability, which reduces the load on the structure. The facility is moored in a structure that goes up from the seabed up and through the platform."

He points out that with changes in the tide, the platform follows the tide.

"The anchoring solution itself also allows constructions to be placed close to each other and will be easily scalable," he says.

Looking for pilot customer and location

Høyning says that Multigen is now looking for locations where it can test the pilot concept with an aquaculture customer.

"We are intensifying this work now before Christmas and after New Year. The [government's] environmental flexibility scheme coming now before Christmas will also make next year a very exciting year for us and the industry," he says.

In such a facility, Høyning believes that you get better control and stable growth conditions for the fish than in open cages.

"In addition, you manage to extract incredibly much more from the licences that are distributed. If you then get an environmental technology scheme that comes on top of it all, it is a potentially quite large catalyst for getting some growth for the aquaculture industry in completely closed facilities," he says excitedly.

Will try out the concept in Nordland

Yesterday, Høyning presented the company's first public presentation of the technology to the municipal council in Vågan municipality.

Lofotposten writes that at Monday's municipal council meeting Høyning said that such a form of aquaculture could be a focus for Vågan municipality.

Multigen Akva has already outlined a concrete opportunity to test the facility in Ytre Austpollen in Nordland, initially for cod farming, which the company presented to the municipal council. The initiative could also open up for salmon farming.

"We wanted to present the concept in our home municipality first and received good feedback on our concept. Of course, it remains to be seen what politicians will decide over time," he tells Kyst.no.

Zero emission facility

Høyning explains that the Multigen concept is built around the principle of zero emissions. All organic waste is collected, and wastewater is purified and filtered for particles, viruses, and bacteria before being returned to nature.

"Collected residual material will enter both established and new circular value chains that the company develops in collaboration with the Norwegian Institute of Bioeconomy. With our technology, we facilitate economic growth, environmental considerations, and at the same time contribute to a safer and more stable production," he explains.

In the closed facility, the intake water will be purified down to the virus level, preventing jellyfish, algae, amoebas, lice, and diseases from entering through the water supply.

"In addition, the facilities are specially designed to provide the fish with the best growing conditions," Høyning says.

The fish also have no obstacles in their swimming path and are offered optimal flow conditions, lighting conditions, operating temperature, and water quality parameters, according to Høyning.

The system is based on being moored but should be easily movable. The facility is based on a module with, among other things, a larger production tank and technology for purifying and treating the water used.

"There will be no permanent interventions in nature," Høyning points out.

Reduced costs compared to land-based

According to Høyning, one of the company's food fish modules is equivalent to 8-12 land-based farming tanks, which typically have a total tank volume of around 45-50,000 m³.

"Here we utilise the water twice as efficiently and only need 1/5 of the area and just one farming tank. When this is considered together, you see reduced costs and energy consumption compared to land-based. Multigen produces more with less, including area," says Høyning.

The biofilter

The RAS facility consists of 'Dynasand' and not traditional plastic chips, which are widely used in land-based RAS facilities.

According to Høyning, Dynasand has the same properties as a biofilter and is also excellent at removing smaller particles, resulting in cleaner water and fewer challenges regarding irritation.

"Dynasand is a Nordic Water product and has been used for water purification for many decades. The system has also been tested in a RAS lab in Bergen with fish densities of up to 90 kg/m³ and showed very good results," says Høyning.