Cell-grown salmon lined up for sushi and poke chains

San Francisco-based Wildtype, which grows salmon meat from cells, has announced distribution partnerships with a US sushi bar chain and a poke bowl restaurant chain, Vegconomist website reports.

SNOWFOX operates sushi bars at 1,230 grocery locations across the US, while Pokéworks is a rapidly growing fast-casual restaurant chain that currently has 65 locations. These partnerships will ultimately allow customers to sample Wildtype’s cultivated sushi-grade salmon for the first time.

However, Wildtype will need to significantly scale its production and gain regulatory approval from the US Food and Drug Administration before a market launch is possible. Wildtype made progress in July when it opened what it claimed was the world’s first cultivated salmon pilot plant. The pre-order list for the salmon was launched in September 2020.

Meat in 5-10 weeks

“Our agreements with Pokéworks and SNOWFOX will help introduce Wildtype’s cultivated salmon to people looking for healthy seafood options that are actually sustainable,” said Justin Kolbeck, co-founder and chief executive of Wildtype.

Co-founder and chief scientist Aryé Elfenbein said: “This is a significant milestone as we move closer to bringing our cultivated salmon to restaurants, grocery stores, and eventually kitchen tables across the US.”

Speaking to Fish Farming Expert magazine in 2019, Kolbeck explained that the company’s cultivated fish meat took just five to 10 weeks to grow. Physically, production was limited only by the size of the growth chamber, but the cost of the liquid used to feed the cells as they multiply into muscle was a financial restraint for volume production.

“For now, we’re looking to move from the kilo phase to the hundreds of thousands of kilos per quarter,” he said at the time.

Pilot plant

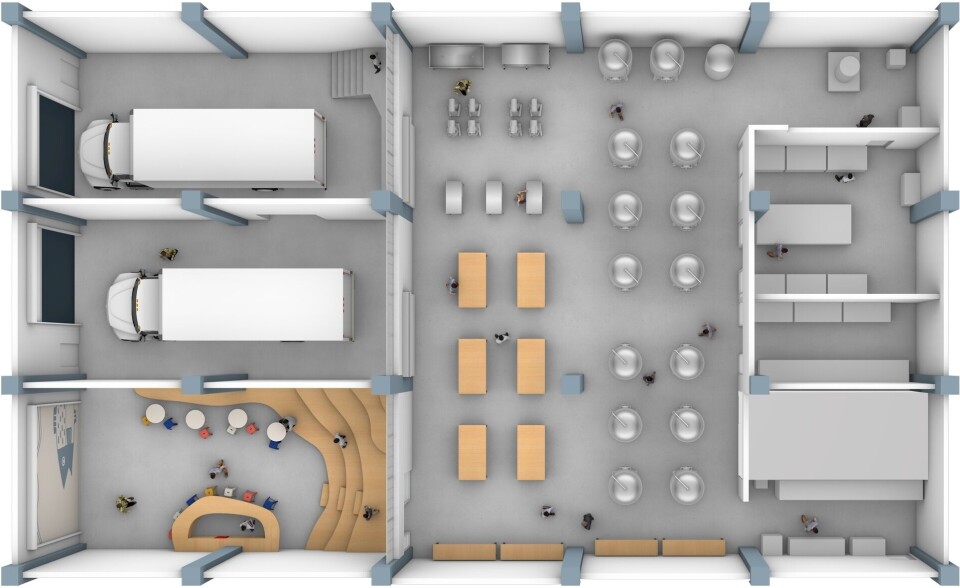

Since then, Wildtype has opened a pilot plant in San Francisco.

“We designed it to work well in an industrial building right in the middle of a bustling city,” the company says on its website. “This means that our food can be produced much closer to the population centres where it’s consumed. Fewer food miles mean a greener and cleaner supply chain.

“Additionally, we built our pilot plant to facilitate the rapid iteration needed in an industry that is still in hyper-growth mode. Rather than bolting everything down and designing an inflexible system, we decided to create a mobile environment that allows us to constantly improve and innovate on our processes. This engineering obsession of ours has already resulted in shorter innovation cycles.

“We envision a production system that can be built in any city in the world. Building demonstration-scale facilities like this proves that we can grow the highest quality seafood anywhere in the world: urban or rural, temperate or tropical. We have already shown that we can build a pilot facility right in the heart of San Francisco that can satisfy most of, if not all, the salmon sushi sold in the city. If we can do it with one facility on a microbrewery footprint, we believe we can reproduce this model all over the country, and indeed around the world.”