Cell-cultivated eel developer hails technological breakthrough

Product will launch in 2026 and may be cheaper than farmed eel, says Israeli start-up

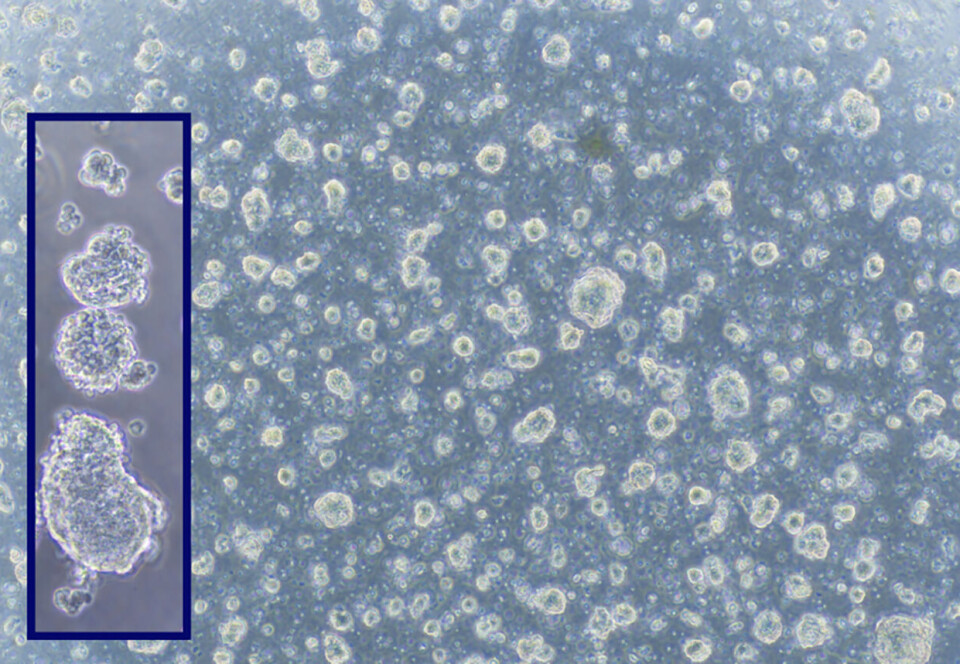

Cell-cultivated seafood innovator Forsea has announced what is says it a major breakthrough in making the production of freshwater eel meat from cells a viable commercial reality. The start-up announced its organoid technology reached a record-breaking cell density of more than 300 million cells/ml, and with minimal and precise use of cultured media ingredients.

Cultured media ingredients are hugely expensive and have been a barrier to viable production of cell-based meat and fish products. Israel-based Forsea said its technology allows for a scalable and highly cost-effective supply for the hugely popular traditional Japanese delicacy, eel (unagi), and it is preparing for a commercial launch in 2026.

According to Forsea, its patent-protected platform involves creating the ideal environment for animal cells to spontaneously assemble into three-dimensional tissue structures with their natural composition of fat, muscle and connective tissue.

This method not only echoes the natural growth process of these tissues in a living animal, giving it a closer-to-nature edge, it bypasses the “scaffolding” stage and is dramatically less dependent on expensive growth factors.

This makes the process highly affordable and positions its cell-grown version to price parity (or potentially lower) with traditional aquafarmed eel, a key challenge the cell-based industry has been desperate to overcome.

After completing its proof-of-concept continuous harvesting process, Forsea said in a press release that it is ready to take production of its cultured fish products to the next phase of commercial scale-up.

“Forsea’s organoid technology requires less capital expenditure than other technologies,” said Roee Nir, founder and chief executive of Forsea.

Achieving this level of cell density with minimal resources will translate to substantial reductions in the unit economics and will bring cultured seafood production to a cost that is actually below the traditional market price

Forsea CEO Roee Nir

“Achieving this level of cell density with minimal resources will translate to substantial reductions in the unit economics and will bring cultured seafood production to a cost that is actually below the traditional market price. This is major milestone for Forsea and validates our vision of making sustainable, high-quality seafood affordable and widely accessible.

Other products

“It also sets a powerful precedent for scaling other cultured seafood products and establishing sustainable alternative supply chains for ecologically sensitive species.”

Forsea is currently focusing on manufacturing cultured freshwater eel due to the immense market potential, particularly in Japan which recorded sales of 140,000 tons in 2023 - 50% of total global sales.

The traditional Japanese dish unagi (eel) is considered a premium delicacy, prized not only for its rich flavour and tender texture but also because of its rarity. Freshwater eel is endangered and cannot be commercially bred in captivity, with farmers instead growing eels captured in the wild.

Strong demand

Forsea says demand for eel far surpasses the industry’s current supply capabilities, translating to skyrocketing prices, and that cell-cultured eel is expected to ease the strain on the world’s eel populations.

“Our recent industry survey shows that cultivated meat production is definitely not a one-size-fits-all approach,” said Elliot Swartz, principal scientist cultivated meat for the Good Food Institute (GFI) that promotes alternative proteins that are plant-based, fermentation-derived, or cultivated from animal cells.

“It’s encouraging to see positive data from companies showing how different methods can address challenges in cost and scale.”