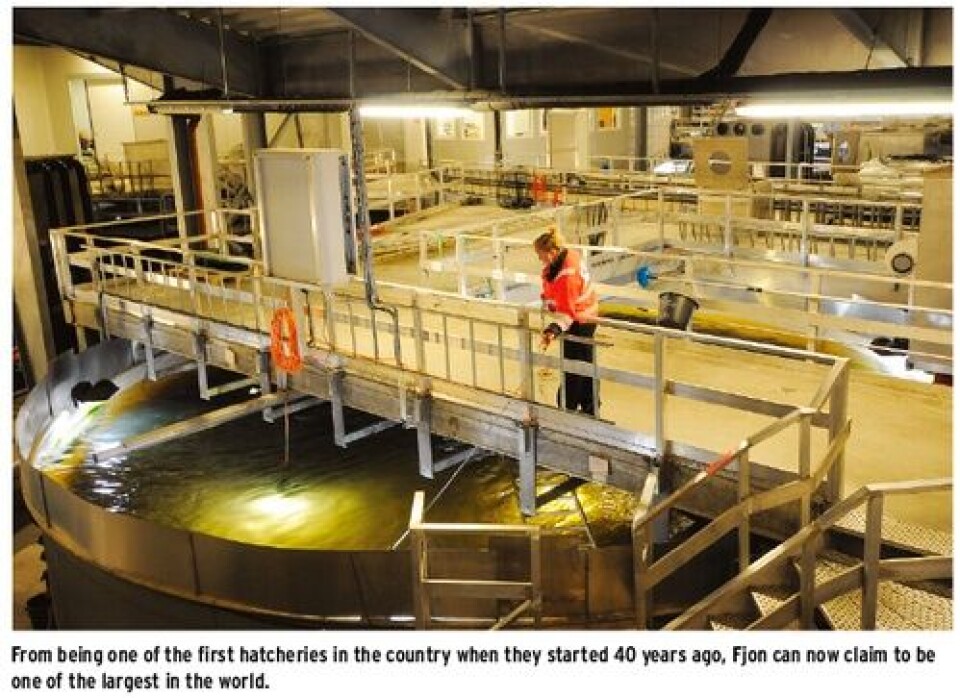

Celebrating forty years of smolt production

By Paul Mugaas Jensen palmj@kyst.no

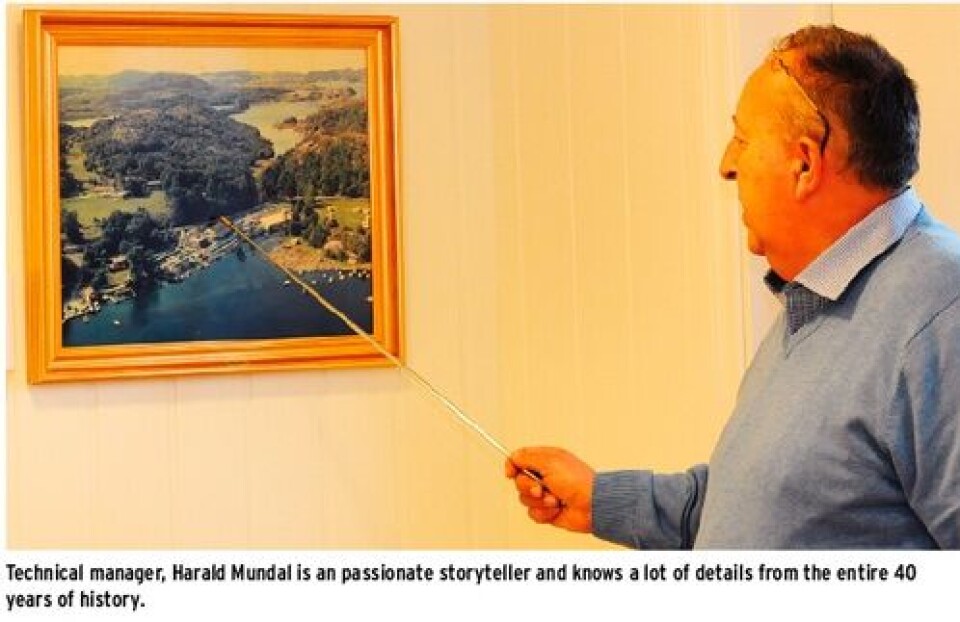

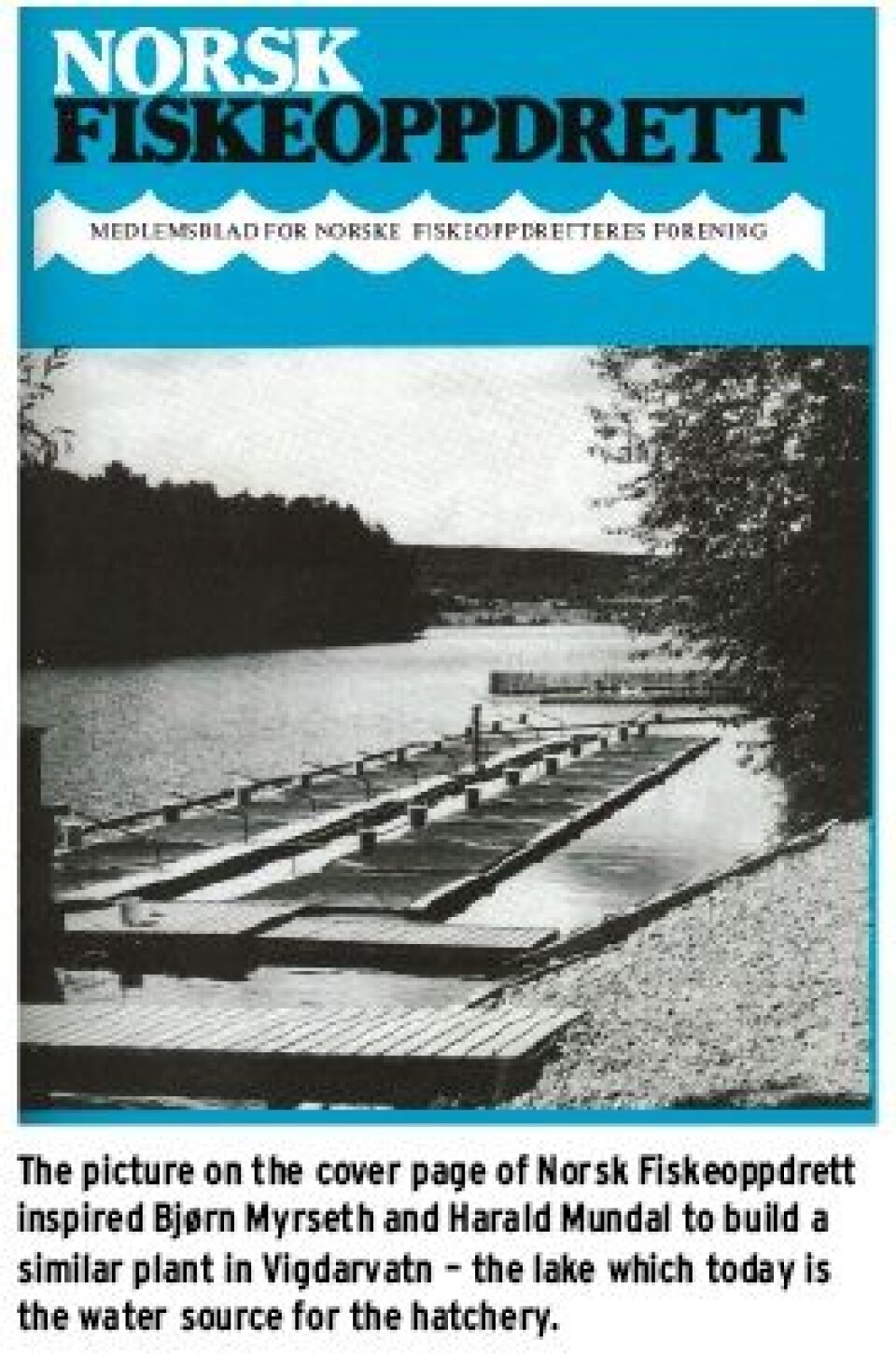

In the early 70 ‘s Jacob Stolt Nilsen from Haugesund, Norway, got an idea to start with farming rainbow trout. But then he needed juveniles. In companionship with Bjørn Myrseth (later the founder of Marine Farms) and Harald Mundal they started to build a hatchery at Fjon. They got the idea for the plant from an article in the magazine Norsk Fiskeoppdrett (the mother company of Fishfarmingxpert). - We saw a picture in Norsk Fiskeoppdrett of a floating hatchery made by Tore Sterner in Lake Siljan in Leksand, Sweden. We modified a bit and built a similar in Vigdarvatn, a lake which today is the water source for the hatchery, he explains. A resource he see as one of the most important factors behind the hatchery.

- This is a very good source of water, he says. The lake of Vigdarvatn is over 7 square kilometers and provides ample water year round. Bjørn Myrseth looked really forward when he chose this place, says Mundal. For about 20 years they also produced juveniles in the lake, but regulatory changes made it illegal. A short river from the lake to the sea was defined as a salmon river. Then the company had to build a new salmon ladder because of the ”large numbers” of salmon. - When I was young I used to fish a lot in that lake, but normally I only caugth char. Only once I caugth a salmon so I question the ”large number”. But rules are rules, so we just had to deal with them, he explains.

Only salmon In the beginning they produced mostly trout at Fjon. But a IPN outbreak in 1975 put an end to the trout production. All the trout were slaugthered.

- But we saved the salmon, he said. IPN became a common disease in almost every smolt farm sites, and the strategy of “stamping out” was abandon. - Thanks to high water quality, it has to date never been found IPN again here at the facility, but at sea the fish are from time to time infected, he said. The water intake is currently only treated with UV radiation before it enters the plant.

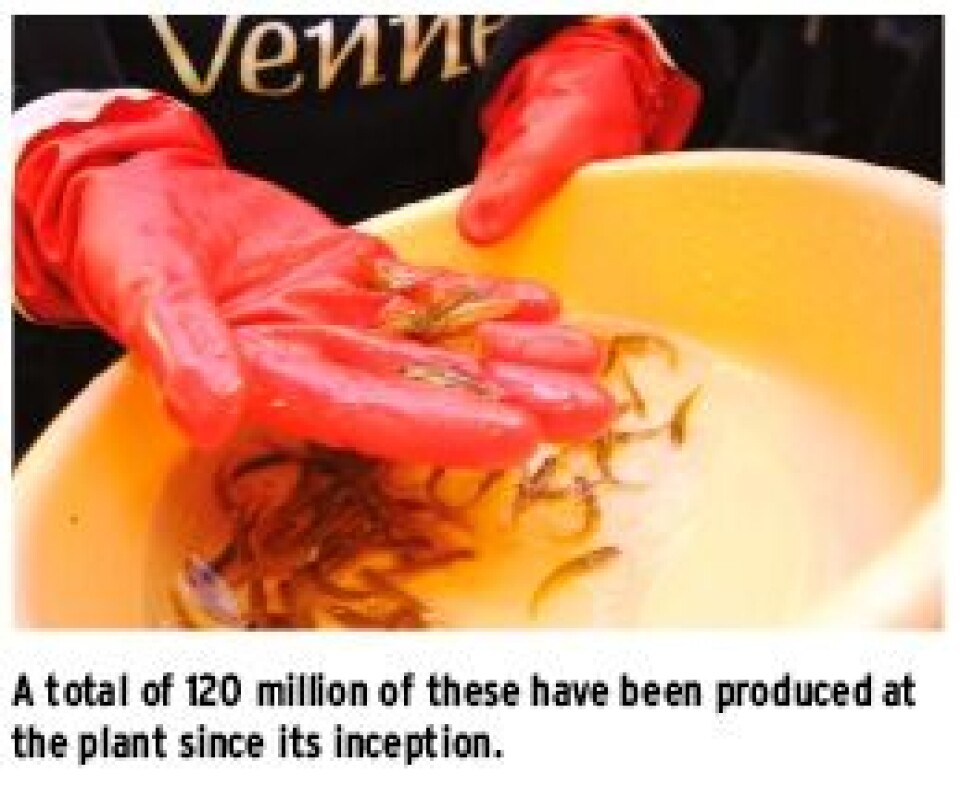

120 million smolts During the 40 years that have passed a lot of smolts have passed through the Fjon bruk plant. Recently the total amount passed 120 million smolts. But it took some years before the size became as big as today. Stolt Sea Farm merged with Marine Harvest in April 2005. Already in November the same year, Marine Harvest anonunced Fjon Bruk for sale . - There were five different players who bid, but Alsaker won and 16. December 2005 the deal was closed.

More extensive than initially planned The original plans from Alsakers point of view to spend around 12-15 million to renew the facility. - But one project after another soon exceeded those estimates. Over the nine years as the owner, Alsaker has spent somewhere around 200 million NOK, says Harald. It has been more or less continuous construction activity since the day the facility was purchased. - At the construction peak three years ago there were 56 external builders in here at the same time.

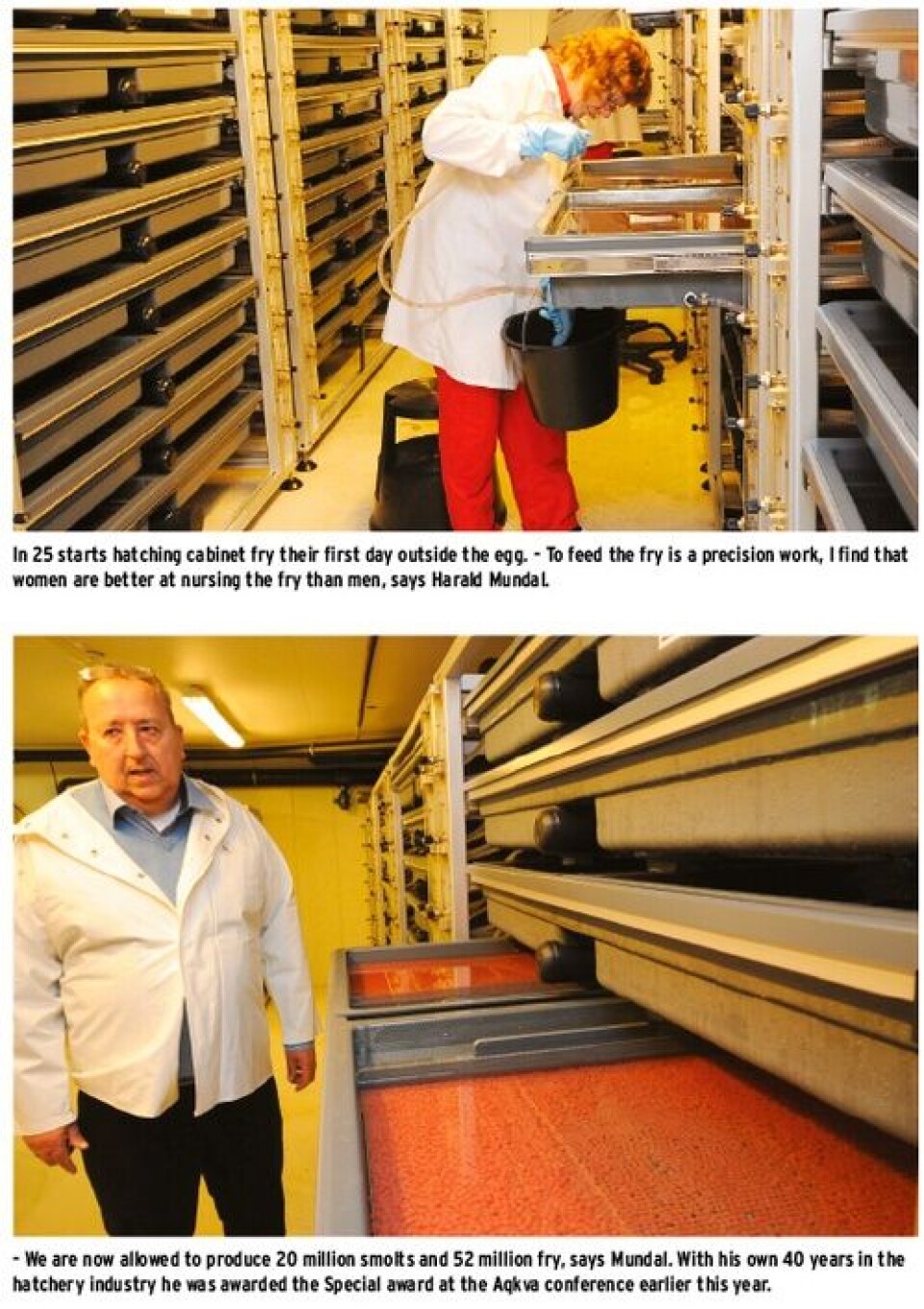

Hatching the eggs yourself All the salmon eggs are hatced at the facility. The first batch is usually bougth from Aquagen, while the second, third and fourth batch often comes from SalmoBreed. The first two batches becomes the autumn smolt. The third batch normally gives a great spring smolt, while the fourth post - which is raised without the use of additional heat, a normal spring smolt. Harald Mundal see a new trend of producing atumn smolt. The cycle is becomming shorter and shorter so the smolt is ready earlier and earlier, it could be ready as early as July. At Fjon Bruk they also produce some large smolts, up to 400 grams, but he does not seem convinced that this is the right strategy. - This smolt does not perform well growth wise when it comes to the sea, so it is quickly obtained, he said.

One of the first heat pump The water used in the plant are mostly heated by heat pumps. - We were probably one of the very first in the country that adopted heat pump for fish. It was indeed a greenhouse technology before, but in the salmon farming industry we were probably one of the first, he says. The heat pump was installed in 1981 and “still runs like a bullet”, accoring to Harald. The raw water which is led into the plant in spring keeps a temperature of four degrees, while out in the fish tanks the water temperature easily can climb to 14 degrees. - When the heat exchanger run at maximum capacity we spend 1000 NOK per hour in electricity. Our latest bill from the electricity provider was 500 000 NOK, says Mundal.

Purifier for drinking water quality In 1996 new regulations were enforced to purify the water that runs out of the facility. Quite a challenge considering that the facility was based on throughput technology. - In the main season we consume 65 cubic meters/minute, but much of the year it is less than that. But it is the largest water treatment plant in Norway. In the Nordic its only the treatment plant in the City of Helsinki ‘s which is supposed to be bigger, he says proudly with a laugh. And water cleaners do their job well . - We purify until we reach drinking water quality. That’s it. Eigther you are in or youre out. Northing between. The mud is separated, lime is added so it gets a pH of 12. Then its pumped it into a big tank on the outside. - Farmers in the area comes and collect the waste and use it as fertilizer on the fields, he explains.

Got Aqkva award Mundal himself also celebrates 40 years in the salmon farming industry this year. At the Aqkva conference at Stord in January this year, he was awarded the Special award. - There have been some amazing years . I feel I have been very fortunate to have gotten to work with so many fine people. He speaks warmly of both Pioneer and first, but also praises the current owner Gerhard Alsaker, also simply called “ father “. - 1986 was the peak year and we got 16.05 NOK as an average price for smolts. But it was when Alsaker came into the scene in 2006 that it really was speedes up.

Solid results all the time From a financial perspective, Fjon Bruk has been in the black in most years and last year was no exception. - Then we got an operating profit of one million NOK per employee, which can not be so unreasonable, he says. But he emphasizes that it is important not to rest too much on our laurels . - Good times and good results are something you`ve already had, you never take them in advance. For the future one have to work, Harald Mundal states.