Happy fish and temperature tracking: how Hiddenfjord switched to sea transport

Faroese salmon farmer Hiddenfjord has reduced the amount of carbon dioxide created in transporting its salmon overseas by around 40,000 tonnes a year (94%) by switching from air to sea freight.

The company, which produces around 18,000 gutted weight tonnes of fish annually, made the switch a year ago and says a unique processing and cooling system ensures the salmon stays fresh on journeys that last up to nine days, depending on destination.

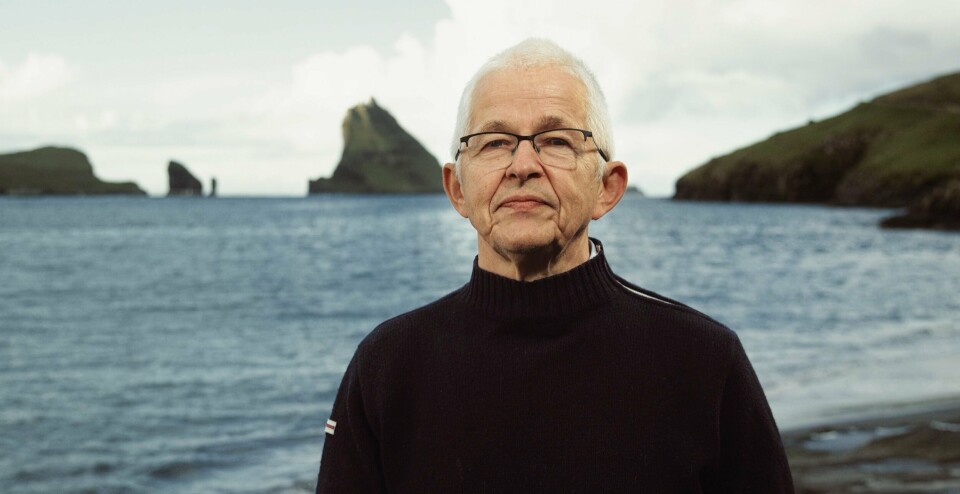

“We have proven that our salmon is still just as good as salmon transported by air,” said chief executive Atli Gregersen, announcing the results of a recent survey conducted by the Consumer Evaluation Center.

Blind taste test

“In a blind test where the salmon was sent with both air and sea transport, more than 100 consumers could not notice the difference and rated both salmon as equally good in categories of taste, texture and aroma.

“By creating a unique process and cooling system and optimising our maritime transport process, where we constantly control the salmon’s temperature, we have kept the quality of our sea-transported salmon high, while we have made the date of the fish last longer.”

Hiddenfjord previously sent its fish to the UK and then on to the United States by plane from Heathrow, a process that took a total of six days.

It stopped using air freight last October and now ships its salmon with Faroe Ship and Faroe Ship’s Icelandic owner, Eimskip. Fish destined for the United States travels from the Faroes to Iceland and from Iceland to Portland, Maine in a journey that has been reduced over the past year from a fortnight to nine days.

Shipping to Spain takes around five days, and approximately seven days to Russia.

Pens towed to harvest stations

Hiddenfjord says its low-stress harvesting method, short slaughter-to-box interval and temperature-controlled shipping containers contribute to its fresh salmon’s long shelf life.

Rather than using a wellboat, the company slowly tows its pens to harvest stations when fish are ready for slaughter. Hiddenfjord says this prevents stressing the fish and results in a higher quality product.

Harvested fish are then transported by lorry to Hiddenfjord’s Sørvagur factory where the salmon are gutted, cleaned, filleted and packed. The boxes are then sealed in refrigerated sea freight containers that are not opened again until they reach the customer. The whole process is completed within three hours of harvesting.

Follow our example

“We believe we have a responsibility, not just to deliver the best possible salmon but to do so in the most sustainable way,” said Gregersen.

In a video made to celebrate the first anniversary of the switch to sea freight, he urged other salmon producers to follow Hiddenfjord’s example.

“You may think that we are now satisfied with being the first in the salmon industry to stop distributing by air, but we are not,” said the executive.

“We would like to see the entire food industry follow our example, for the future of the industry and the benefit of our planet.”