Canada: Aboriginally-owned tank farm to be stocked with Atlantic salmon

Odd Grydeland

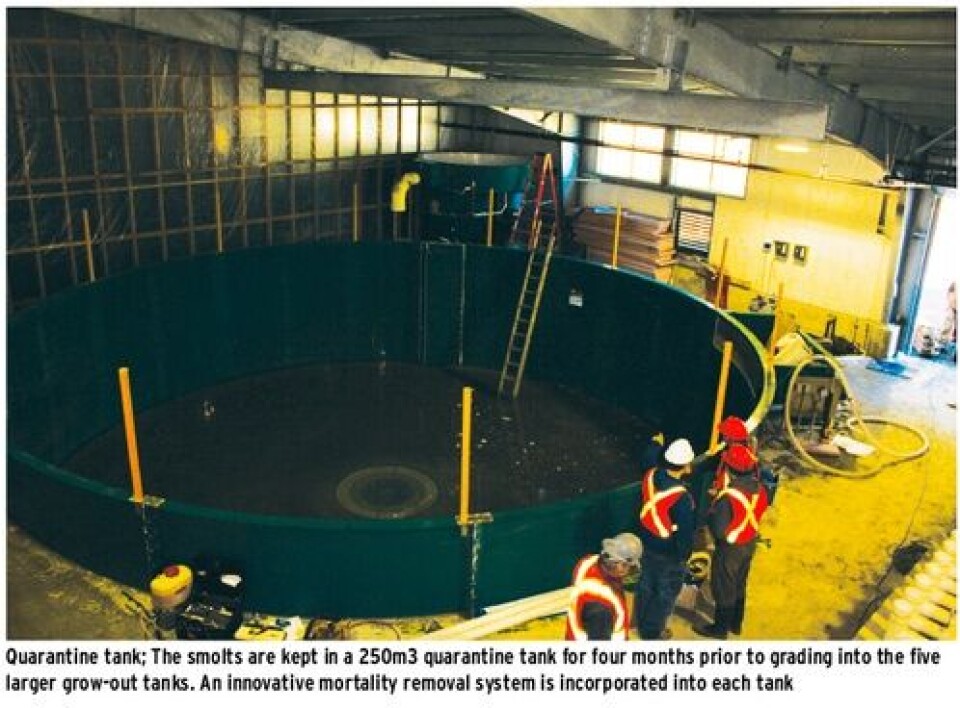

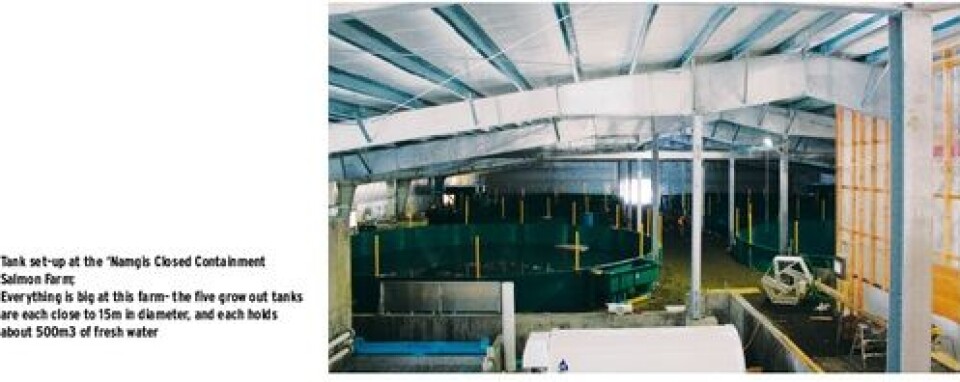

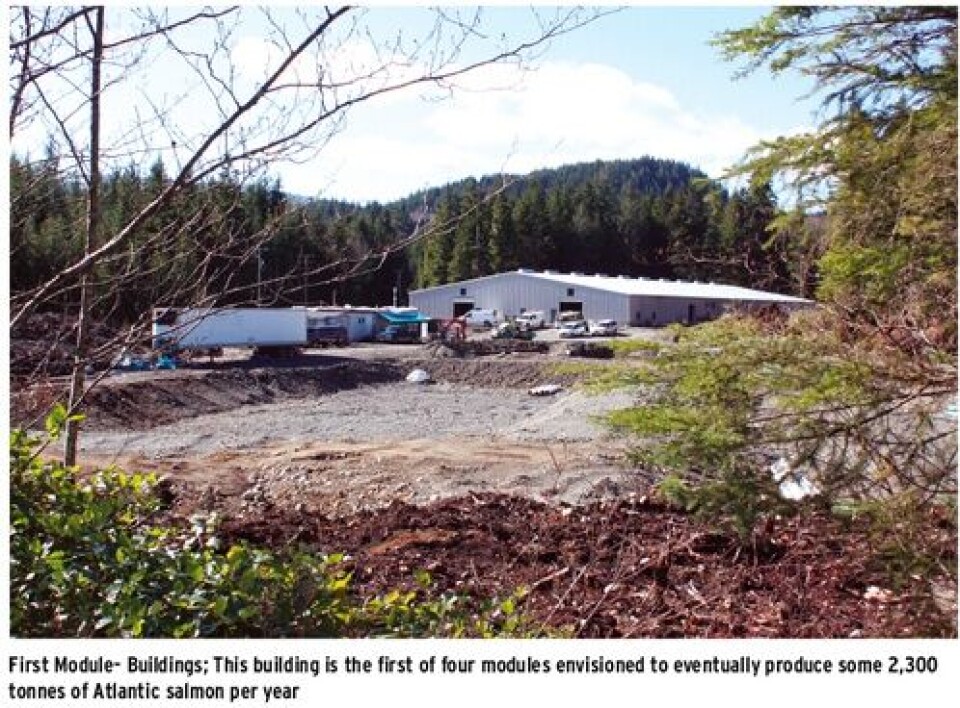

The Chief of the ‘Namgis First Nation on Northern Vancouver Island has never been a fan of the twenty-something conventional salmon farms in the Broughton Archipelago near the Band’s Traditional Territory along the Nimpkish River. Bill Cranmer has been quite vocal in his opposition to the net pen aquaculture industry, and now he is overseeing the start-up of a CAD$ 9.5 million (~€ 7.1 million) land-based salmon farm pilot project which is expected to produce about 390 tonnes of dressed, high quality Atlantic salmon per year (470 tonnes round weight). The first smolts are being introduced later this month (March, 2013) and they are coming from one of Marine Harvest Canada’s two hatcheries/smolt production facilities in the area. The ‘Namgis Closed Containment Project plans to “demonstrate the commercial viability of producing Atlantic salmon for table food in a land-based, closed containment recirculating aquaculture system”, according to a recent Project Backgrounder. It is envisioned that once such commercial viability is documented, another four similar modules will be built on the ‘Namgis’ reserve near the Nimpkish River just south of Port McNeill, where the Band has been operating a salmon enhancement facility for different species of Pacific salmon since 1978. The new facility consists of two 250 m3 tanks- one for use as a quarantine facility for incoming juvenile salmon, and a second tank to be used for the depuration (purging) of the fish prior to harvest in order to remove any potential off-flavour often associated with production of fish in RAS systems. The Atlantic salmon will be grown to harvest size in five circular, 500 m3 tanks, and three groups (cohorts) will be introduced each year.

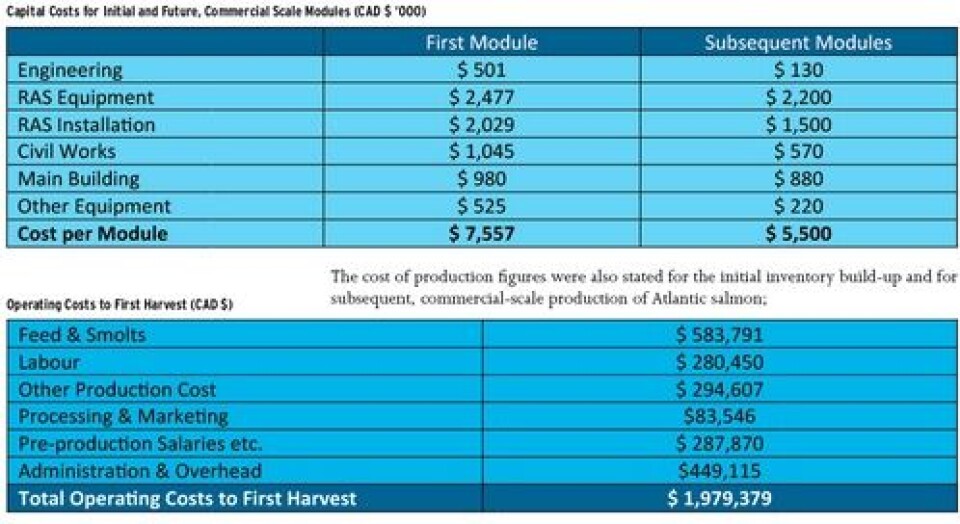

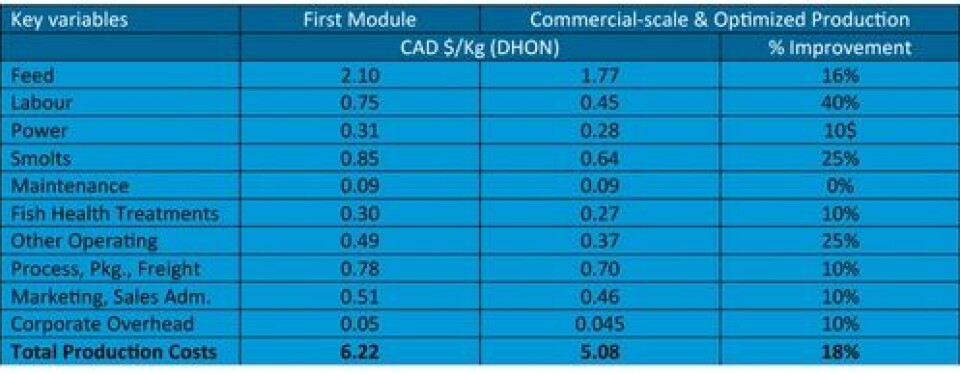

The project proponents include the SOS (save Our Salmon) Marine Conservation Foundation, which was formed in 2006 with a mandate to “resolve environmental impacts associated with ocean net-pen salmon farms”, and the organization “Advocates industrial migration to land-based closed containment”. A SOS representative recently told a news reporter that the project is expected to show that Atlantic salmon produced at this RAS facility will use 30 per cent less feed than a conventional net-pen salmon farm and that the fish will reach harvest size (5-6 Kg) in half the time, meaning that the first harvest is expected to take place sometimes next March (2014). The RAS-produced Atlantic salmon is also expected to fetch a premium selling price of up to 60% compared with traditionally-produced salmon, as the organization claims that there is a growing consumer demand for fish produced this way. The ‘Namgis First Nation and the management of the project have both committed to provide all data of importance as the tanks are installed and the first fish are being introduced. A list of anticipated capital costs and operating expenses was provided during a workshop held on Vancouver Island last year.

On a per kilo basis, the operating costs are stated to be an estimated CAD $ 6.22 for the first 390,000 kilos of Atlantic salmon (dressed, head-on product), and $ 5.08 per kilo of subsequent, full scale production.

There is no mention in the figures provided by the operator of the cost of depreciation of the CAD $ 7.6 million capital investment of the first module, or the estimated CAD $ 23.5 million (~€ 17.6 million) cost of building the rest of the facility, which would include four additional modules as well as a CAD $ 1.5 million (~€ 1.12 million) hatchery. If this cost is hidden in one of the variables listed (Other Operating or Corporate Overhead), the amortization period must be longer than twenty years.

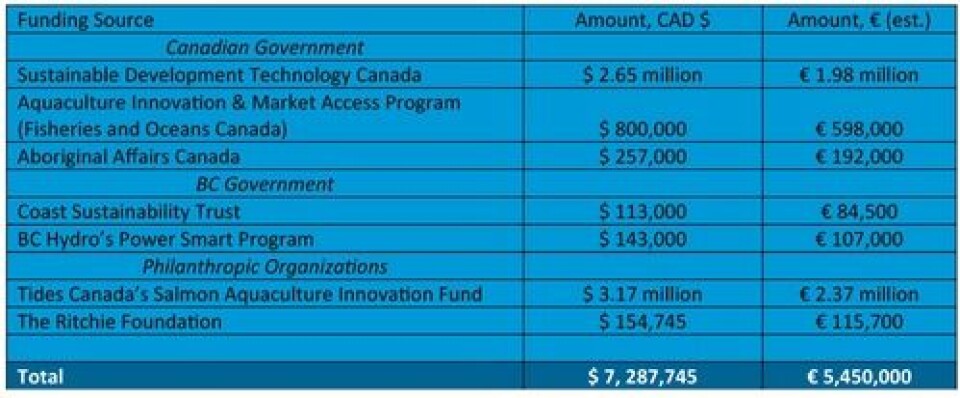

The lack of accounting for the cost of depreciation can be understood when it comes to the first module, which was funded largely by non-repayable grants from the Canadian and British Columbia governments as well as philanthropic organizations that brought in considerable funding from among else the Unites States’ Gordon & Betty Moore Foundation through Tides Canada. If the project was built using conventional sources of financing, the first module would have incurred interest costs and it would still be prudent to include a depreciation cost of almost one CAD $ per kilo produced, assuming the infrastructure was to be depreciated over a twenty year time frame. This still does not include any allowance for the value of the land required for the project.

Up until late last month (February 26, 2013) the ‘Namgis Closed Containment Project had received funding for the construction and operation of the facility to the tune of over CAD $ 7.25 million (~€ 5.4 million), in addition to a stated contribution of CAD$ 1 million (~€ 748,000) provided by the owner, the ‘Namgis First Nation. The Band also contributed the land to build the facility on.

If the stated cost estimates and premium price point were to come true, the ‘Namgis Closed Containment Project would be expected to see an operating surplus of approximately CAD$ 1.7 million (~€ 1.27 million) at today’s market price of approximately US$ 3.- per pound (~€ 5.- per kilo) for conventionally produced farmed Atlantic salmon delivered to Vancouver or Seattle. If the anticipated premium price (of 60% over the going price for 5-6 Kg Atlantic salmon) is not realized, the result would be reduced by approximately CAD$ 1.5 million (~€ 1.1 million), leaving an operating result of about CAD$ 145,000 (~€ 108,000)- with no accounting for depreciation or land costs. These numbers are based on the assumption that all of the 390 tonnes of product will be sold as Premium grade fish at the going rate for such fish. In reality, salmon produced in farms in B.C. (and everywhere else) will see some fish of less than Premium quality, and these fish will fetch a lower price in the market.

The ‘Namgis project will be producing mixed-sex Atlantic salmon in almost pure fresh water, and experiments with this technology have shown that 80% of the males of such populations will mature early- at a weight of 2 – 3.5 Kg. ea. (Steve Summerfelt, Conservation Fund Freshwater Institute- Aquaculture Innovation Workshop, Comox, B.C. Nov. 5-6, 2012). In one experiment a total of 40% of all the fish grown in fresh water were removed as early maturing males. It is possible to reduce this early maturation by using all-female or late maturing strains of salmon, the study authors suggested, and this has been shown on conventional farms using different species of salmon. In an interview with the ‘Namgis project’s Operations Manager, Cathal Dinneen told FishfarmingXpert that this was indeed one of the uncertain variables of the project, but that a certain percentage of extra smolts will be entered in order to allow for some early maturing salmon. These maturing fish will be graded out after about 7.5 months on site.

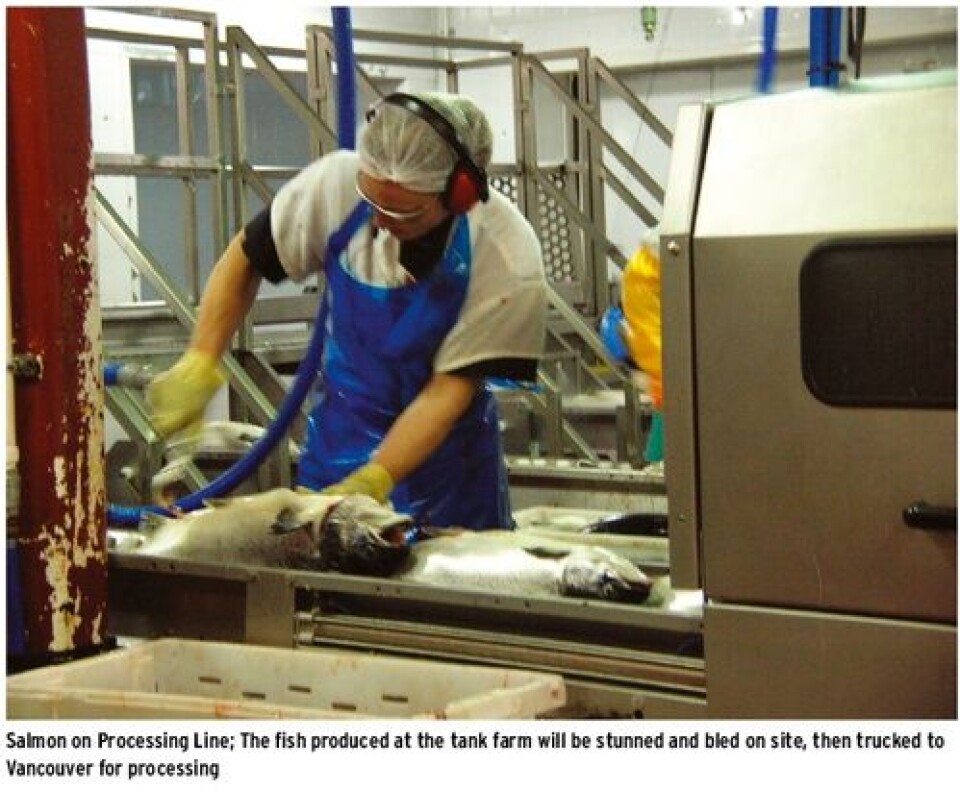

Mr. Dinneen said that the production plan calls for the stocking of three groups of Atlantic salmon smolts each year- one every four months. All of the fish are envisioned to be approximately 100 gram ea., and the first delivery which is expected to take place later this month (March, 2013) will consist of approximately 23,000 fish. The plan is to keep the fish in the 250 m3 quarantine tank for four months, at which time the fish are expected to reach a size of approximately 6-700 gram. The fish will then be graded into the larger grow-out tanks, where they will be kept for another 8-10 months, up to harvest size of 4-5 Kg, and at a maximum density of 50 Kg/m3. The fish will be kept in the depuration tank for up to 10 days prior to stunning, bleeding and shipment to Vancouver for processing- a four hour drive plus a ferry trip that takes close to two hours. Mr. Dinneen said that he hopes to get the fish to the plant in Vancouver before the onset of rigor. Harvesting is expected to take place every two weeks, which could result in a void of available product in the market place between deliveries.

The second batch of smolts is envisioned to be grown to a higher density of about 75 Kg/m3, meaning that this delivery will consist of approximately 34,500 fish. And the final cohort of Atlantic salmon for the ‘Namgis project will be close to 58,000 fish if the planned maximum density of 90 Kg/m3 is to be achieved. The business plan for the project has an allowance for 7% of the originally stocked fish to be lost to routine mortalities, but Mr. Dinneen suggested that the actual rate will be much lower- likely less than 1%. The fish will have been vaccinated against the most commonly found bacterial diseases (furunculosis and vibriosis), as well as against IHNV (Infectious Hematopoietic Necrosis Virus). The company does not expect to use any antibiotics or pesticides, although an allowance in the budget for “Fish Health Treatments” refers mainly to the use of salt for the control of fungus.

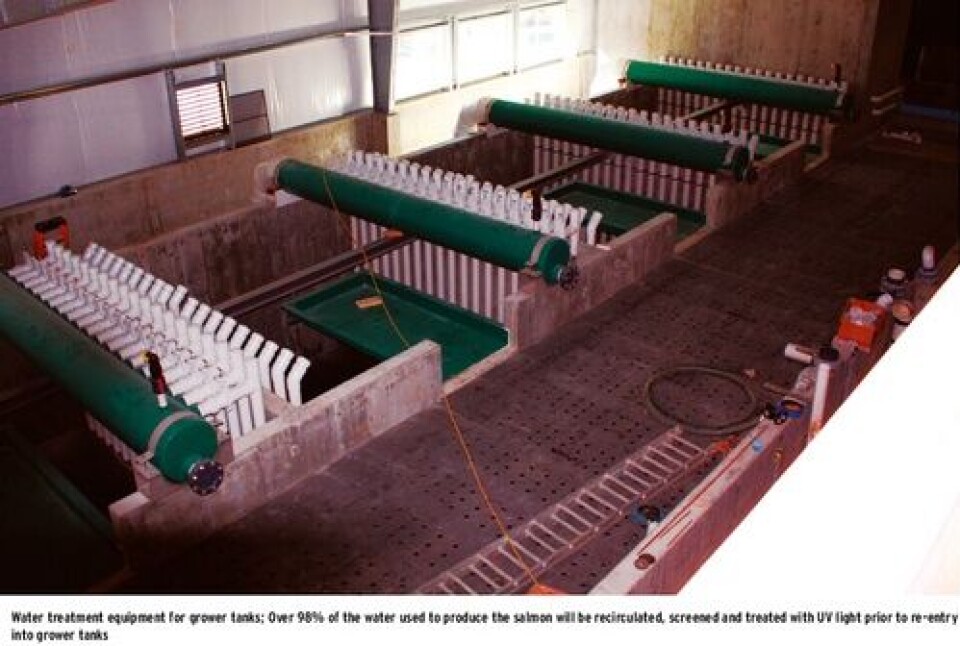

The anticipated faster growth of these Atlantic salmon will be a result of growing the fish at temperatures that will allow for maximum feed intake. The water coming from sub-surface wells will be heated from an ambient ~9°C to 15°, using heat extracted from the large CO2 strippers and energy recovery ventilators, a heat pump as well as from heating cables installed in the floor of the grow-out tanks. The intake water will be treated with an Ultra-Violet sterilization system, and there is also a built-in plan for the disinfection of the discharge water, to be activated for a period of four months for the first batch of fish, and for a period of one month after delivery of subsequent cohorts if no fish health problems have occurred. This disinfection will be carried out using a chlorination/dechlorination process. The estimated volume of about 675 liter per minute discharge water will be screened for solids and pumped into one of two large, 4,000 m3 dry infiltration basins, from which the water will seep through the porous gravel/sand soil and eventually dissipate into the ocean some 1.5 Km downstream- a process estimated to take about seven days.

Staff of the ‘Namgis project told FishfarmingXpert that their number one priority is to build a hatchery in order to have full control of the entire production cycle. Budget estimates include a provision of CAD$ 1,5 million (€ 1.12 million) for this purpose. If and when the additional four modules are built, the production level is expected to reach about 2,300 tonnes per year. The project anticipates a biological feed conversion rate of 1.05.