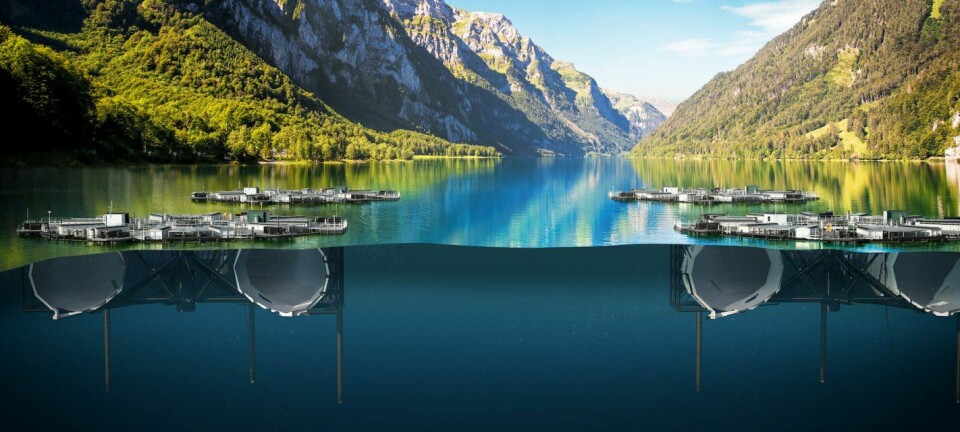

Coming full circle: first Marine Donut is almost ready

Polyethylene fish farm weighs just under 500 tonnes and has permit for 1,100 tonnes of biomass

The construction of the first Marine Donut fish farm, which started in the spring of 2022, is now nearing completion.

The Donut, made by thermoplastics specialist Bluegreen in conjunction with salmon farmer SalMar and other partners, is the world’s largest construction in thermoplastic and towers over the company’s quay at the Frierfjorden in Bamble, southeast Norway.

“The external diameter is a whopping 55 metres, the height over 17 metres and the volume of 22,000 cubic metres. The weight is just under 500 tonnes,” said Geir Andresen, project manager and partner in Bluegreen.

“The construction is entirely built in polyethylene, a recyclable thermoplastic. As soon as a section has been completed, it has been lifted over and welded to the main structure. Bit by bit, the ‘Donut’ has taken shape.

20km of welding

“For those interested in plastics, I can tell you that 8-10 tonnes of welding wire have been used in the project, and the total length of extruder welding is around 20,000 metres!

“This is ground-breaking work. We have built large constructions in thermoplastics before but are breaking our own records with this project. It’s a result of outstanding design, engineering, and plastic craftsmanship.”

It was Nils-Johan Tufte, managing director and partner in Bluegreen, who first got the idea to create a doughnut-shaped closed floating fish farm.

“With the challenges associated with escapes, lice and local negative environmental impact from sludge and waste, I quickly realised that closed farming is the solution. But for the industry to use these facilities on a scale that is acceptable, it must also be cost-effective,” said Tufte.

“The doughnut shape maximises volume and minimises weight.”

Improved functionality

The Marine Donut was granted a fish farming permit under Norway’s development scheme and the plans are still the same as they were then, according to Tufte.

“The concept must be carried out in line with the measurement criteria for original commitments on development permits. We have nevertheless improved the product’s functionality and details in collaboration with SalMar,” Tufte told Fish Farming Expert’s Norwegian sister site, Kyst.no.

The Marine Donut is a closed flow-through facility with sludge collection and has a permit for a maximum 1,100 tonnes of biomass. According to Bluegreen, the facility is well suited to the production of both post-smolt and harvest-sized fish.

The Donut has a water intake below the lice layer – the top 10 metres of the water column - and the closed structure prevents escape.

Competitive cost

“By eliminating the lice problem, the traffic light system should be able to be utilised positively,” said Tufte, referring to Norway’s method of increasing or reducing production allowances on the basis of perceived impact of lice from farms on wild salmon.

“We hope that there will be a new licensing regime specifically aimed at the type of technology that Marine Donut represents, so that the concept can contribute to achieving the growth ambition that Norway has set within the farming industry.

“Our aim is to demonstrate that despite the fact that the Donut has a higher capital expenditure than traditional cages, the costs per kg of fish are competitive. The costs of feed and medicine go down, fish health and fish quality go up. In addition, the facility provides smarter logistics for the farmer. Overall, this results in increased profitability.”

For the January edition of Norsk Fiskeoppdrett (Norwegian Fish Farming) magazine in 2022, Tufte stated that the purchase price for a Marine Donut including ultraviolet purification of intake water was in the range of NOK 110-130 million. Since then, prices for several materials used in the Donut have gone up. Tufte states that Bluegreen will not comment on capex for a full-scale pilot plant.

Watch an explanatory video of the Marine Donut concept here.