Salmon lice trap 'has reduced the need for treatments by 40-100%'

According to the company's chief executive, Blue Lice's trap can now show solid results. 'Farmers have fewer delousings and less lice infestation for the fish,' says Karoline Sjødal Olsen.

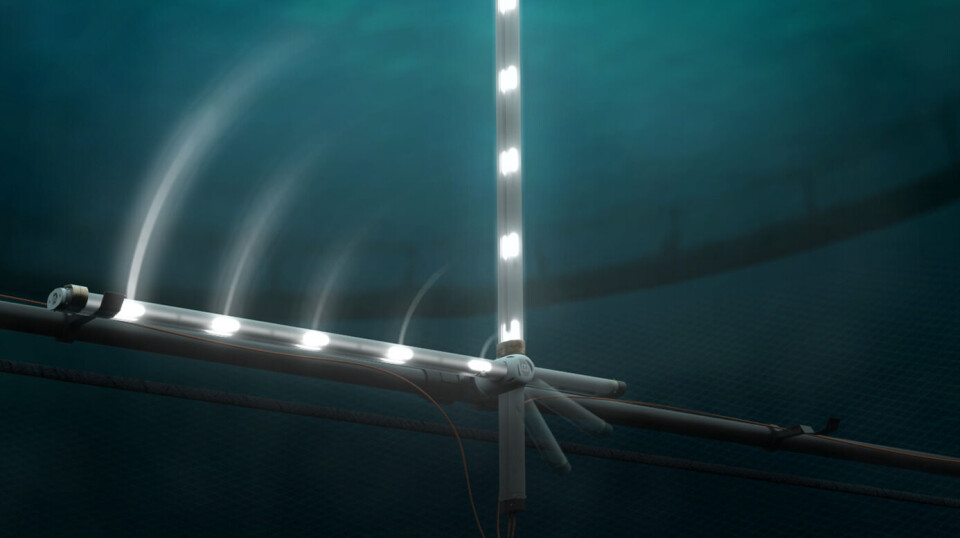

The equipment and technology company Blue Lice AS has developed and patented technology that uses light signals and pumps to capture lice larvae before they reach the fish.

The technology uses specific light signals to attract free-swimming lice larvae, which are then sucked in using a pump and collected in a filter. The system is mounted on the farm's frame mooring at a sufficient distance from the pens so that it does not affect the fish or daily operations.

- Increased demand

Karoline Sjødal Olsen, chief executive and co-founder of Blue Lice, told Fish Farming Expert's Norwegian sister site Kyst.no that 2024 has been an important year for the company, during which it has seen that the focus on prevention among farmers is much higher than it has been previously.

"The number of inquiries to us from farmers in 2024 has increased significantly. We have secured several new contracts, and many of our customers have chosen to repurchase our system."

Another highlight for the company has been that the service team has managed to increase the uptime of their systems to nearly 100% this year.

"We have achieved this through continuous improvements of the system with the help of good feedback from engaged customers," said Sjødal Olsen.

'Reduced treatment needs'

Blue Lice reported that it can show solid results at all locations where its equipment is installed.

"In the period 2020-2024, we have seen very positive results with our customers. At all locations, we have reduced the need for treatments by 40-100%. In addition, we have delayed the time until the first treatment at all locations."

Olsen referred to a specific example where a customer recently harvested a generation without any treatments in the spring, after previously having several treatments in the same period.

"This generation was harvested with an average weight of five kilos, compared to 3.8-4.0 kg in the previous generation, which is very good in our eyes. Here, Blue Lice compares the lice situation against historical data on previous fish releases," explained Sjødal Olsen.

The company also points to good results from its sampling using DNA technology (DDPCR), performed by NINA, the Norwegian Institute for Nature Research.

80,000 larvae in a day

"We have documented the capture of up to 80,000 salmon lice larvae (copepodites) in one day. Without measures, these salmon lice larvae would have developed into sexually mature lice 2-3 weeks after capture. That week of capture has thus reduced the reproduction of a total of 74 million salmon lice eggs in one week. These new lice larvae would have spread in the sea, potentially infecting other locations and continuing the cycle," said the CEO.

Kyst.no contacted two of the farmers who have used the system. Line Ellingsen, chief executive of Ellingsen Seafood, said the company was involved in the test phase of Blue Lice, but is not using the system now.

"We couldn't see the significant effect of Blue Lice, but as mentioned, we were in a very early phase," she said.

Jeanette Galtung Døsvig, communications manager at Grieg Seafood, said the farmer had previously tried Blue Lice at two locations in Rogaland.

"We have used it in combination with other measures, and therefore cannot say anything about Blue Lice in isolation," she said.

Blue Lice 2.0

Blue Lice is also working on the final touches of the sea lice trap 2.0, where the latest version is equipped with a lift/lower function.

"After 2.5 years of development work, we are now launching a new salmon lice trap that can clean itself. This allows the system to remain undisturbed throughout the entire production cycle. Before the New Year, this system will be used by two customers. It has been important for us to grow at the right pace so that we have knowledge and good service at all levels," said Sjødal Olsen.

Blue Lice 2.0 is intended to be a smarter and more autonomous system.

"The new system allows for two-way communication between the lice traps, which in the long run means that the system can be monitored from both the feed barge and anywhere in the world. The self-cleaning light rod is one of the biggest improvements. The lice traps can now clean themselves at a frequency we can control, allowing the system to remain undisturbed without the need for manual cleaning and handling."

She pointed out that this reduces the need for external and internal resources for the farmer to maintain the system.

"Furthermore, the system includes a raise/lower function, which makes it easy to lower the lice traps when needed, for example, when wellboats need to enter the site. Each individual light rod is now also independent and not connected in series like the previous generation of the system. This means that each lice trap can be replaced without affecting the rest of the system," she explained.

- Research-based documentation

Blue Lice is also part of a research project named "The Lice Trap", where their system will be installed at an aquaculture facility operated by research organisation SINTEF. There, researchers will document and quantify the effect of Blue Lice's trap technology as a preventive lice measure.

"We are very proud to have received a large allocation of support from FHF (Norway's Fisheries Research Fund), for a project in collaboration with SINTEF, SalMar, NINAgen, and the Norwegian Computing Centre, which is a great recognition for us and the technology we have developed. With solid research-based documentation from the project, we can finally document the positive effect we have seen through our results since 2020," said Sjødal Olsen.

The sub-goals of the project include documenting and comparing the effect through testing and monitoring the technology in field trials over an entire production cycle at sea, where various methods are used, such as mathematical lice models, weekly lice counts, real-time monitoring of lice caught by the system, and quantitative analyses of lice DNA from the system's filter stations.