ScaleAQ cages chosen for Cermaq iFarm

Salmon farmer Cermaq has chosen ScaleAQ to supply the aquaculture equipment for its iFarm project, which will scan and treats fish individually.

ScaleAQ will supply its Midgard cage system, including a floating collar, winch and Midgard net, in addition to a net cover and net tube that will enclose the iFarm unit being developed by BioSort.

The first edition of the iFarm is scheduled to be deployed at Cermaq’s Martnesvika site in Nordland, northern Norway this summer.

‘Enough muscle’

“It was crucial to bring on board a partner who offered the best expertise and has enough muscle to ensure that we make iFarm a success,” said Cermaq’s iFarm project manager Karl Fredrik Ottem in a press release.

“ScaleAQ is a partner we have worked with before, and we know they deliver solid solutions.”

ScaleAQ was formed last year as a result of the merger of Norwegian companies Steinsvik, Aqualine, AquaOptima, and Tasmanian aquaculture software provider PanLogica, and has created a new department working on innovation and development across the companies.

Individual treatment

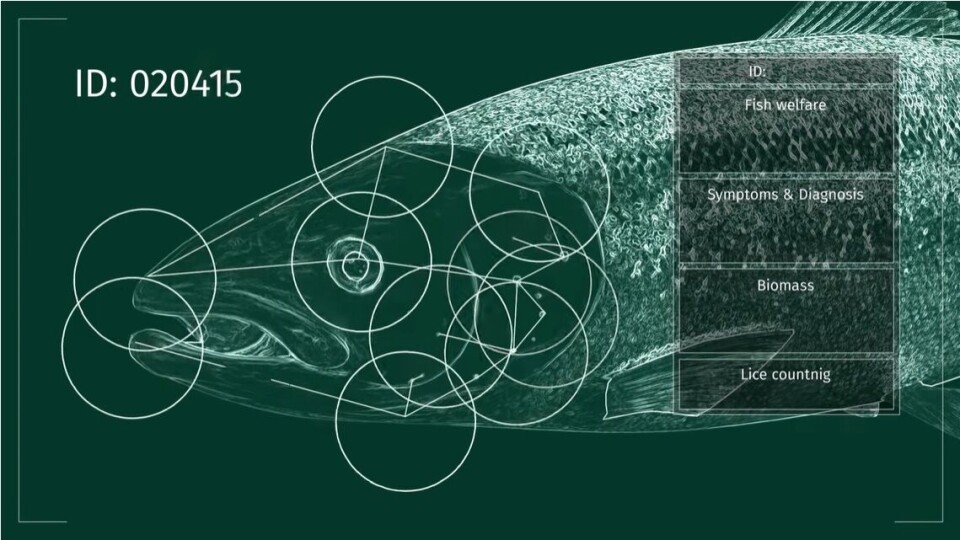

The iFarm, which is still under development, uses image recognition and the identification of each individual salmon to monitor the status and development of every single fish in a cage, including growth, health and lice.

Individual fish can be sorted out, and only fish that need to be will be treated for health issues. The sensor-based solutions for the iFarm are being developed by BioSort, based in the Oslo area.

Cermaq, which is owned by Japanese company Mitsubishi, has been awarded four Norwegian development licences for the iFarm. This allows the company to grow approximately 3,000 tonnes of extra biomass to help offset costs of development.