Umitron launches real-time analytics system for shrimp

Aquaculture tech firm Umitron has launched a real-time artificial intelligence-based analytics solution for shrimp farming.

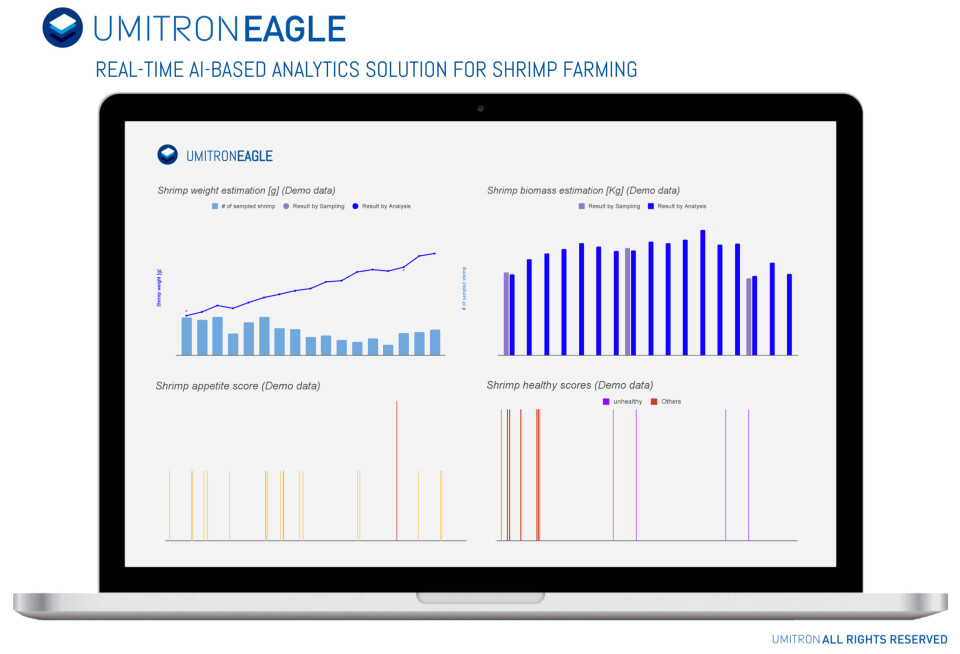

Umitron, based in Japan and Singapore, says Umitron Eagle uses advanced AI detection to track multiple real-time biological conditions and other factors in highly turbid and intensive production environments.

In a press release, Umitron said that despite seeing exceptional growth, the shrimp industry is still plagued by many issues ranging from disease outbreaks, general health management and poor environmental management protocols that can lead to mass mortality events and disrupt the supply chain.

Limiting factor

Umitron claimed poor uptake and adoption of digital technology by shrimp producers has also been one of the limiting factors stunting growth, both economically and sustainably.

“While solutions exist to remotely control feeding (via timer-based automatic feeders) and monitor environmental parameters using sensors, they are currently unable to analyse the real-time conditions of the shrimp,” said Umitron.

“This is further exacerbated by the fact that most farming environments have poor visibility (i.e., high turbidity) and that digital transformations have been slower and more limited for shrimp than their fish counterparts.”

CP Foods

In 2019 Umitron announced that it had started a joint project with Charoen Pokphand Foods (CPF), the largest shrimp business enterprise in the world, and it has since developed a solution to assess shrimp production conditions in real-time using customised AI algorithms.

These include but are not limited to real-time appetite analysis, health and growth conditions, and biomass.

“While important, these metrics are not always actively charted and monitored due to a lack of available resources and solutions on the market, be it manpower or automation-wise,” said Umitron. “With Umitron Eagle, producers can now optimise their feeding protocols easily and automatically using real-time analytics. In addition to the current partnership with CPF, Umitron would also like to extend this solution to other shrimp farmers to improve the operations at their production sites.”

Improved FCR

The company claims producers can expect to successfully achieve:

- improvements in feed conversion ratio, growth and harvest amounts for each crop

- improved biosecurity measures and work protocols

- a reduction in feed wastage which may contribute to undesirable environmental conditions such as poor water quality and highly-turbid conditions and require frequent water changes

- better long-term farming management protocols and optimised operations using the accumulated production data

Umitron’s other products include Pulse, which provides a variety of ocean environmental information for fish, shellfish and seaweed farmers, and Umitron Lens, a portable fish body measuring system.