SCP feed product ‘offers alternative to RAS purging’

KnipBio has announced that fish fed a diet containing 5% of the company’s KnipBio Meal single cell protein (SCP) have significantly lower levels of geosmin and methylisoborneol (MIB), the compounds responsible for giving fish grown in recirculating aquaculture systems (RAS) an earthy or musty flavour.

The Massachusetts-based company said in a press release that its product is the first nutrition-based alternative to the industry practice of purging fish to remove off-flavours. In addition to reducing geosmin and MIB, feed trials identified additional strong metrics in fish fed a KBM diet, including strong weight gain, growth time, and survival rates.

Larry Feinberg, chief executive of KnipBio, said: “Off-flavours can be a serious issue for RAS farms. The standard solution to address this is to conduct a purge process where the fish are transferred to tanks containing clean water and feed is removed. The process can last as long as 14 days and during this time, the fish lose body mass.

“Our trials indicate the need for purging can potentially be eliminated when fish are fed a diet containing KBM, resulting in significantly improved RAS economics, better process reliability, and enhanced consumer satisfaction.”

Trout and barramundi

KnipBio partnered with New Hampshire RAS trout grower BlueStream Aquaculture and Massachusetts barramundi (Asian sea bass) producer Great Falls Aquaculture to conduct initial feed trials.

Keith Wilda, co-owner of BlueStream Aquaculture, said: “Every time you take fish off feed, you lose mass. You don’t just lose visceral fat, you take the risk of quality changes in the texture of the fish, so the shorter the purge time, the better. We raised fish through the grow-out phase on a KBM diet and have been impressed by the results to date. Our fish performed well in terms of growth and the taste was superb.”

Feinberg added: “After we completed our grow-out trials with BlueStream, we invited some of Boston’s leading restaurateurs to sample fish fed KBM diets at a tasting event we dubbed ‘Feed-to-Fork’. We wanted to both showcase the quality of RAS-raised rainbow trout and demonstrate the positive benefits of KBM to flavour.”

‘Clean taste’

Jimmy Liang, owner of JP Fuji Group, the largest pan-Asian restaurant group in New England, used BlueStream trout raised on KBM to create multiple dishes for the event. Liang said: “We prepared the trout in several ways, with an emphasis on revealing the essential flavour of the product. The quality of the fish we served was outstanding. One of the dishes we prepared was trout sashimi and I was really impressed by the clean taste. It’s better than any trout I have had before.”

Feinberg said: “Following these initial trials, we conducted formal feed trials to understand how concentrations of geosmin and MIB changed over time in trout and barramundi fed KBM.

“For each species, one tank held a control population fed a standard aquaculture diet while the second held fish fed a balanced diet containing 5% KBM. The two tanks shared a common water source.

52% lower geosmin

“After four weeks, the concentration of geosmin was >52% lower in barramundi fed KBM than in the control, even as the concentration of geosmin in their shared water supply increased more than four times.

“For KBM-fed fish, up to a 55% lower concentration of MIB was observed.

“We will continue to expand feed trials to include other species, and to find the optimum feeding regime to maximise overall performance. It is important to drive the concentrations below the threshold where a consumer can detect off-flavours, and our biotechnology can drive results even lower.

“KBM is already an FDA-approved feed ingredient and is being manufactured at commercial scale. At a time when RAS production is headed towards major expansion, improving quality, reliability, and consistency is exactly what the industry needs.”

Ethanol by-product

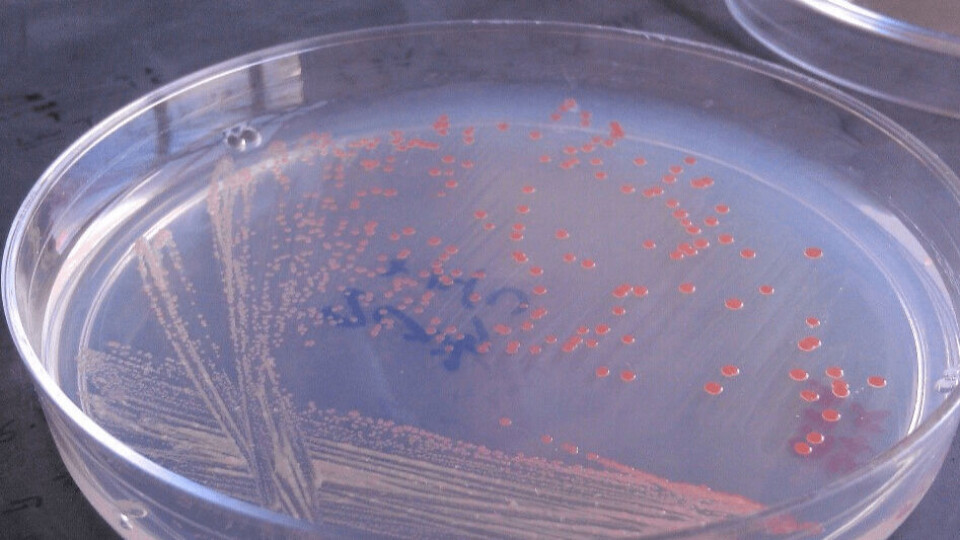

KnipBio’s patented process uses methylotrophic bacteria to produce single cell proteins for KnipBio Meal.

In June 2019 it announced a breakthrough in its fermentation research that enables the company to produce SCPs from condensed distillers’ solubles (CDS), a residual by-product of ethanol fermentation.

“Using CDS dramatically reduces our feedstock costs, allowing KnipBio Meal to be competitively priced with traditional aquafeed proteins,” the company said at the time.

“CDS is cheap, there’s a lot of it, and because it is a waste stream, it is inherently sustainable with virtually no environmental footprint.”