Can a porous cage bag solve the salmon lice problem?

A Scottish entrepreneur believes he has found a solution to salmon farming’s sea lice problem by using a nylon mesh that blocks lice from entering net pens but allows water to flow through as normal.

Andrew Bett, who runs Forfar-based Salar Pursuits Ltd, used knowledge gained from a career in the paper and packaging industry to identify and source 150-micron woven nylon filtering mesh capable of blocking sea lice larvae, which have a size of 175-200 microns.

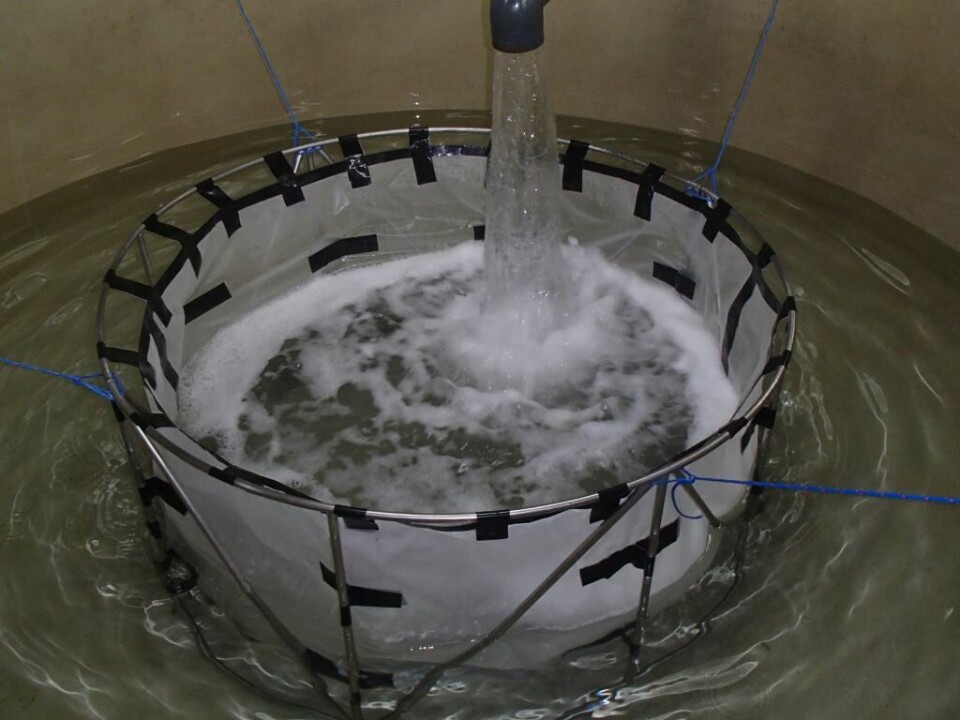

His intention is to use the mesh to create a bag that would fit inside a net pen, creating a semi-closed containment system without the need for water to be constantly pumped into the enclosure.

University testing

Bett has been working on the idea, trademarked Smoltscreen™, for four years, and has now published results of tests by the University of Stirling. These included placing fish in a small-scale mesh enclosure to act as a chemo-attractant for 900 nauplius-stage sea lice in a tank with a water flow of 75 litres per minute.

No lice were found in any of 14 water samples taken from the enclosure over a 295-minute period.

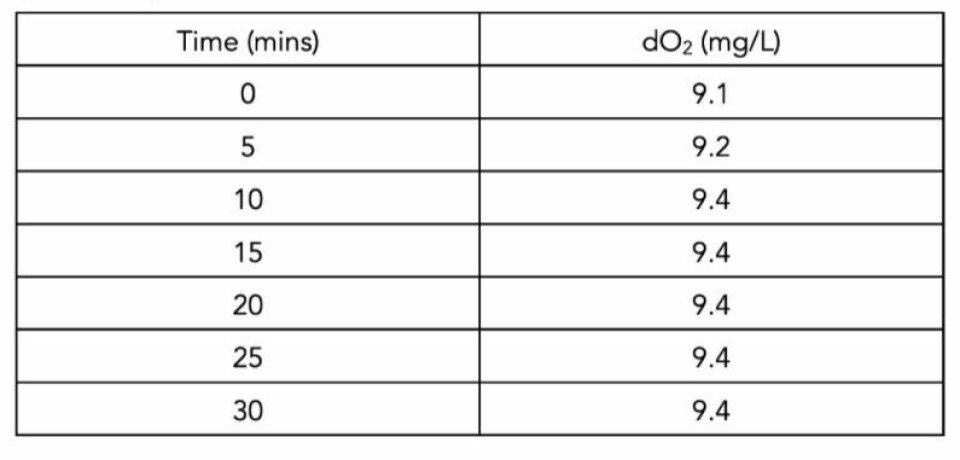

Separate tests on dissolved oxygen (dO₂) levels in the enclosure showed dO₂ dropping slightly from 9.6 mg per litre to 9.1 mg/L over 60 minutes with a normal water flow of 0.58 metres per second directed at the mesh above the surface. When the flow was directed at the mesh under the surface, the dissolved oxygen level in the enclosure improved from 9.1 to 9.4 after 10 minutes. It stayed at that level for the remaining 20 minutes of the test.

Full-scale trial

Bett says the next stage of the project is to make a full-sized Smoltscreen enclosure and test it on a salmon farm. He is hoping publication of the test results will interest a salmon farmer in Scotland or Ireland, but if that doesn’t happen, he plans to use the salmon aquaculture test farm run by Ireland’s Marine Institute in Cashel Bay, Connemara.

“I have made a preliminary booking for this site, and we could run a trial in the 50-metre circumference cage. It’s not a big one but it’s a proper enclosure,” he tells Fish Farming Expert.

“We’re working with (net maker) Swan Net Gundry in Killybegs, who are going to make the enclosure for us. The supplier is a US supplier of the material. It can be sewn in panels to any shape or size.

“We’ve done as much as we can with prototype testing. We’ve sent the small enclosure out through breaking waves on the coast, and we’ve had material attached to rocks underneath low tide for weeks on end to see how it fouls and how it cleans with pressure washing. But the acid test is a farm trial.

“We’re not yet committed to the Connemara trial. If anyone has an enclosure that’s fallowed, we can put one of our Smoltscreens into it.”

Bett has applied for patents for the Smoltscreen, which he says is at Technology Readiness Level 6 (TRL 9 is the level for commercial deployment). There’s a lot of work still to do, he adds.

“But we’re in a good place now to run trials at sea, and it’s not expensive material. I have produced commercial successes in the paper and packaging industry, and I’m not fazed about the next steps at all. I’d be amazed if it doesn’t work,” says Bett, who studied zoology and has a passion “for all things very small and aquatic in the invertebrate department”.

“At a prototype level to TRL 6 we’ve solved the sea lice problem. We know that we can maintain a 15 kg/m³ stocking density inside one of our prototype enclosures with a perfectly acceptable oxygen exchange at 0.58 metres per second tidal flow,” he says.

Tensile strength

“There are sites with very low flow and there are sites with higher flow, and how a very fine nylon mesh sitting inside an existing cage is going to behave in different tidal flows is yet to be seen. That’s a challenge I’m sharing with my net manufacturers, who are working on the designs (for the enclosure). I’ve got one design already from Mørenot. They needed to test whether this material could be sewn sandwiched between polyester webbing which makes a secure seam bond. That means that every 1.8 metres – that’s the width of the loom – you’ve effectively got a skeletal structure that’s providing a lot of the strength.

“It is a fine material, the tensile strength is about 50% of an existing net, and that’s pretty impressive. The structure of the cage is effectively created by the existing netting, and we just pop ours inside.”

Bett expects the enclosure to sit against the top of the existing net and have a shallower depth of 10-12 metres.

Flow resistance

“One reason for that is because we want to moderate the amount of resistance to tidal flow, and also because salmon are inclined to shoal and live quite contentedly in the top six metres,” he explains.

“The density ratio is because of all that water that’s underneath the fish, but they don’t really occupy it that much, and we hope that any lost volume – if you were still stocking to 15 kilos - would be compensated with reduced mortality. And farmers wouldn’t have to fallow their cages either.”

Waste would have to be collected, possibly by using a remotely operated vehicle, and the porous surface would have to be kept clean to ensure water flow.

Bett also envisages the use of two 50 hp submersible pumps that would pump cold, clean, filtered water into the enclosure, at a rate of 20,000 litres/minute from 20 metres deep, in the event of sea temperature or algal events impacting oxygen levels.