Land-based salmon farmer doubling production capacity to 15,800 tonnes

Salmon Evolution signs contracts for Phase 2 of 31,500 gwt facility

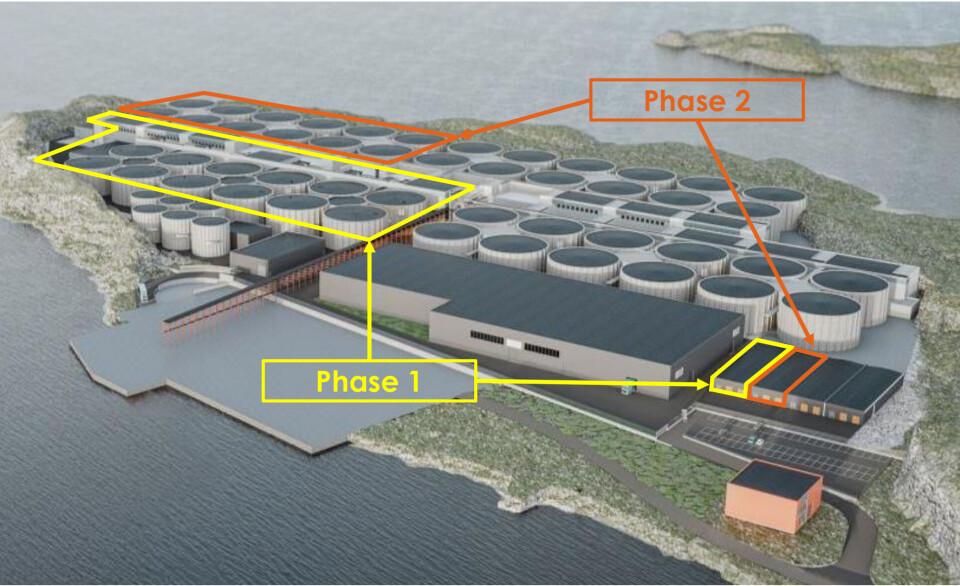

Salmon Evolution has signed contracts for the second phase of its planned 31,500-gutted weight tonne land-based salmon farm in Norway, it announced today.

Phase 2, which will estimated to cost NOK 1.6-1.7 billion (£118m-£125m), will double production capacity from 7,900 gwt to 15,800 gwt.

HENT, one of Norway’s largest general contractors, for design and construction of civil works, and Artec Aqua, which delivered much of Phase 1, will have responsibility for the design, construction, and commissioning of the salmon farming facility.

Salmon Evolution has already started with initial groundworks and plans to be in a position to start phase 2 construction works by year end 2023.

Sixth generation

“We have now been producing salmon for almost 15 months at Indre Harøy and are already on our sixth generation,” said Salmon Evolution chief executive Trond Håkon Schaug-Pettersen, whose company is now stocking new batches of smolts every two months as it builds up to steady state production in its first 12 tanks.

“Throughout this period we have seen very strong biological performance, and although we have also had challenges, we have demonstrated that we are capable of effectively handling demanding situations.

“We firmly believe that our highly scalable concept will play an important role in future aquaculture, delivering high quality salmon at conventional industry cost levels.”

AGD challenge

The primary challenge faced by Salmon Evolution was a rise in in its very low fish mortality levels in April caused by amoebic gill disease after pathogens entered its hybrid recirculation / flow-through system despite intake sea water being filtered and UV (ultraviolet) treated. Aggregated mortality level for each batch at 29 April ranged from 0.3% - 7.9%.

On 23 May the company reported that it had taken quick and appropriate measures to rectify the situation, including reduced temperatures and feeding, increased UV dosage on intake water, rapid culling of batch 2 in a historically strong market and freshwater treatment of all remaining fish groups with a wellboat.

“We are very satisfied with being back in production mode and are currently seeing good appetite and normal mortality levels across the facility and very much look forward to continuing our growth plans while at the same time incorporating the lessons learned in the next phase,” Schaug-Pettersen said today.