New energy source for offshore aquaculture tested

With the United States beginning to establish the legal groundwork for off-shore aquaculture development, researchers are focusing on new technology that could be used in exposed areas of the coast. One such research project is trying to develop a method of harnessing the ocean energy in order to supply offshore installations with electric power sufficient to sustain the operation of a set of submergible cages, as described in the following article by New Hampshire Union Leader correspondent Jim Kozubek;

A company experimenting with wave power conversion attempted to test its device two miles off the coast of Newburyport, Mass. to see if ocean waves in the region are strong enough to generate energy for offshore aquaculture. Resolute Marine Energy, Inc. of Watertown, Mass. has a system, which makes use of a buoy undulating on the ocean's surface to create a pumping action with an arm to a platform below. Bill Staby, CEO of Resolute Marine, said currents were unexpectedly strong at the site of deployment, near the mouth of the Merrimack River, and a mooring line snapped, ending the test before the converter made it into the water. Staby said his company will try again, probably next month.

Resolute Marine's wave power converter could be used in conjunction with offshore wind farms to even out the surges of power generated by wind, but its first application is powering aquaculture pens, which are used for producing fish. "We are going to try to develop wave energy for cost-effective utility scale grid energy," said Staby, but he added: "Aquaculture needs power now to move offshore." Staby's converter was developed in part by Massachusetts Institute of Technology professor Cliff Goudey, with a $90,000 Phase I grant from the National Oceanic and Atmospheric Administration, and converts wave power to compressed air power.

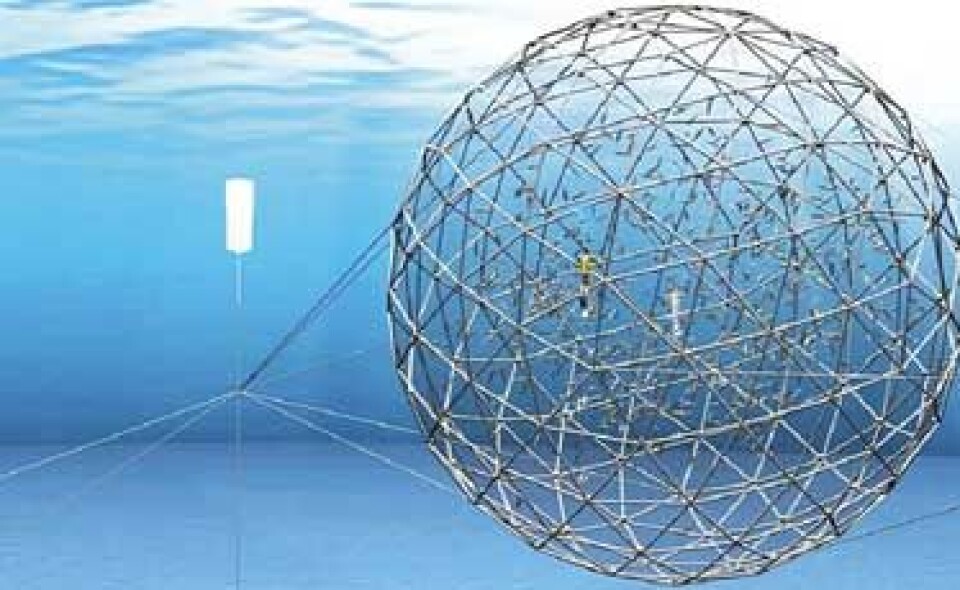

Steve Page, CEO of Ocean Farm Technologies, Inc. of Searsmont, Maine, is now a lead manager on the project. Page has developed a 64-foot, 3,600-cubic-meter cage made of polyethylene and wire mesh to grow fish deep in the ocean. "As finfish aquaculture moves into deeper ocean sites, we will need sustained, autonomous sources of power," Page said. AquaPod net pens are designed to be moored at a stationary, licensed site at a depth near 100 feet.

Staby's converter creates compressed air that could power auto-feed systems, lower the cage, or in the future, power propellers to move the cage from place to place. Goudey developed a propulsion system consisting of twin, 8-foot, 6.2-horsepower propellers that can power the cage out to its station in the ocean. The system was demonstrated on AquaPod last year at SnapperFarm, Inc. in Puerto Rico. Ocean Farm has sold the $135,000 cage to fish farmers in Puerto Rico, Panama, Mexico and South Korea, but so far it has been sold independently of the propulsion system.

George Nardi, chief technology officer for GreatBay Aquaculture, LLC, a land-based fish hatchery in Portsmouth, wants to put the AquaPod into commercial use this spring at a moored site near Sorrento, Maine. Nardi said once the company has learned to safely operate the AquaPod, the cage could be used to farm fish off the coasts of New England.