The automatic choice: machine built to select best fish for breeding

Researchers in the Netherlands are working on the use of machine vision to select the best fish for breeding more quickly and accurately than it can be done by humans.

The work is being carried out by Wageningen University and Research (WUR) and Aalten-based company Dorset Identification (Dorset ID), which develops decoders and antennas for radio frequency identification (RFID) systems.

The shape and colour characteristics of farmed fish are assessed to allow a breeder to decide which fish will be used for further breeding.

Faster and more objective

This is normally done manually, but with machine vision techniques a higher number of samples and more variables can be measured in a shorter time. In addition, software is more objective and has a higher repeatability than a human observer.

The project is part of AquaIMPACT, a programme funded by the European Union that aims to integrate the fields of fish breeding and nutrition to increase the competitiveness of EU’s aquaculture of Atlantic salmon, rainbow trout, gilthead seabream and European seabass.

The device WUR and Dorset ID are developing measures various variables such as the 2D and 3D shape, colour and properties of body parts such as eyes or belly.

Genetic database

The fish are manually removed from the breeding tank and placed on a conveyor belt. An algorithm merges the colour and shape characteristics of the fish with genetic information from a database.

After analysis a selection algorithm will classify the individual fish in real-time to be selected or not to be selected for further breeding. The device then mechanically sorts the fish two groups.

For one fish, the entire operation is completed in approximately 30 seconds, reducing handling stress and increasing the speed and efficiency of breeding programmes.

Hardware

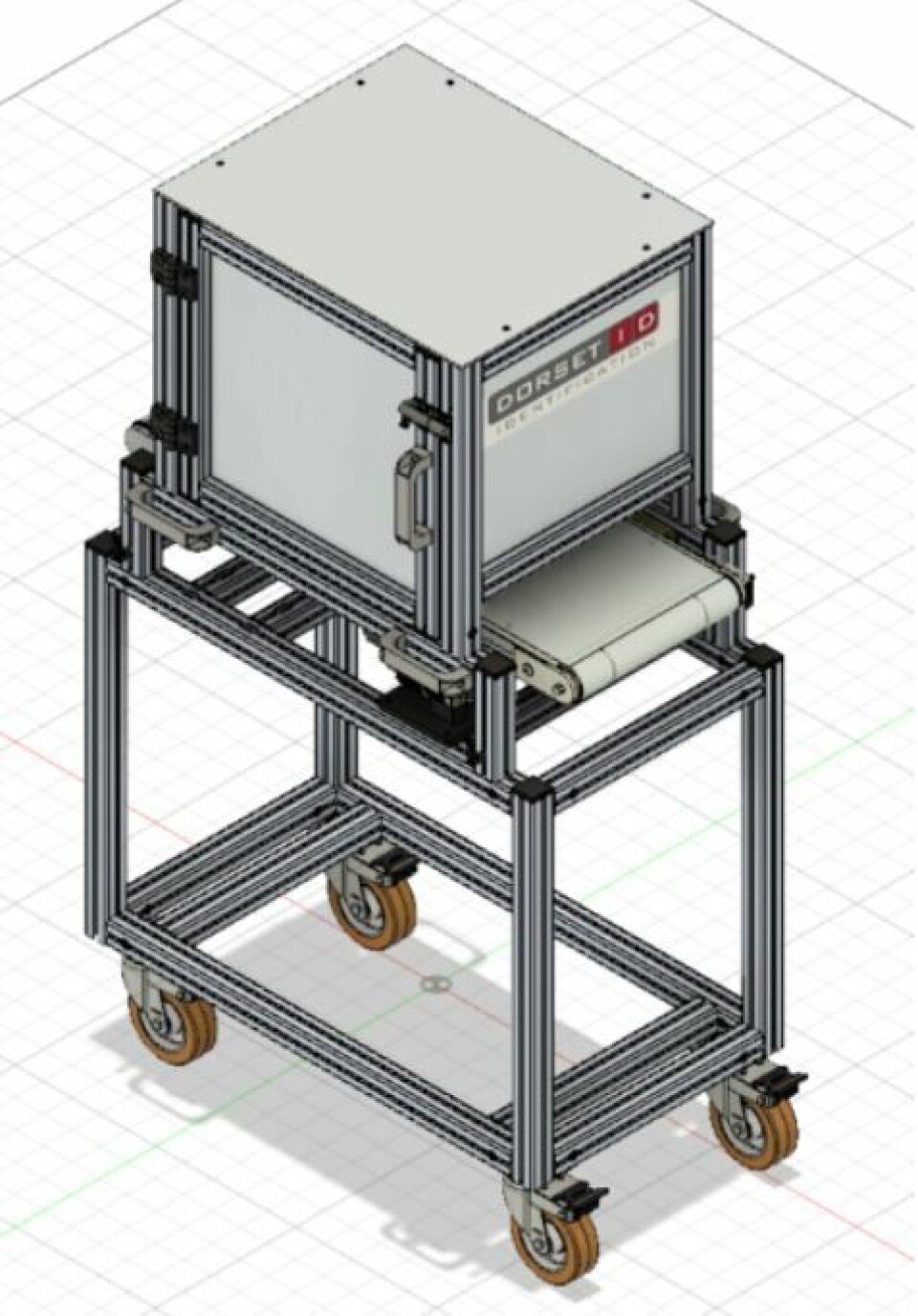

Dorset ID is responsible for the hardware of the system, i.e., identification of the fish when passing an antenna, providing the hardware to capture images, providing the right condition to make the required images, transportation of the fish and the automatic selection mechanism to select those fish that meet the selection criteria.

The frame of the sorting system has been finished, and the conveyor belt finally arrived after having been delayed due to Covid-19. “So, now we are to continue assembling the line and hope to run some initial test end of June,” said managing director Roland Stump in an article on the AquaIMPACT website.

The device will have the following characteristics:

- Mobility for the easy transport.

- Can be operated in outdoors in variable daylight conditions.

- Can automatically read RFID tag of individuals, measure weight.

- Real-time classification and sorting.

- Measures calibrated colour 2D features and can extracts landmarks

- 3D image analysis for volume reconstruction.