Ex-Mowi Scotland and Ireland farmer sees closed containment as the future

Production expert takes the 'bait' offered by Norwegian developer

The former production manager of salmon farmer Mowi Ireland, Roar Paulsen, has joined Norwegian floating closed containment specialist Aquafarm Equipment as senior vice president.

“Roar knows the industry, and the industry knows Roar. Both abroad and in Norway. We therefore put out a bait and got a bite. We think this is a perfect match,” said Aquafarm chief executive Jarle Lønning in a press release.

Paulsen was operations manager in Ireland for 18 months, from January 2023 until June this year. Prior to that, he was production director for Mowi Scotland from May 2021. He also spent nine years as production director for the mid-Norway division of salmon farmer Lerøy.

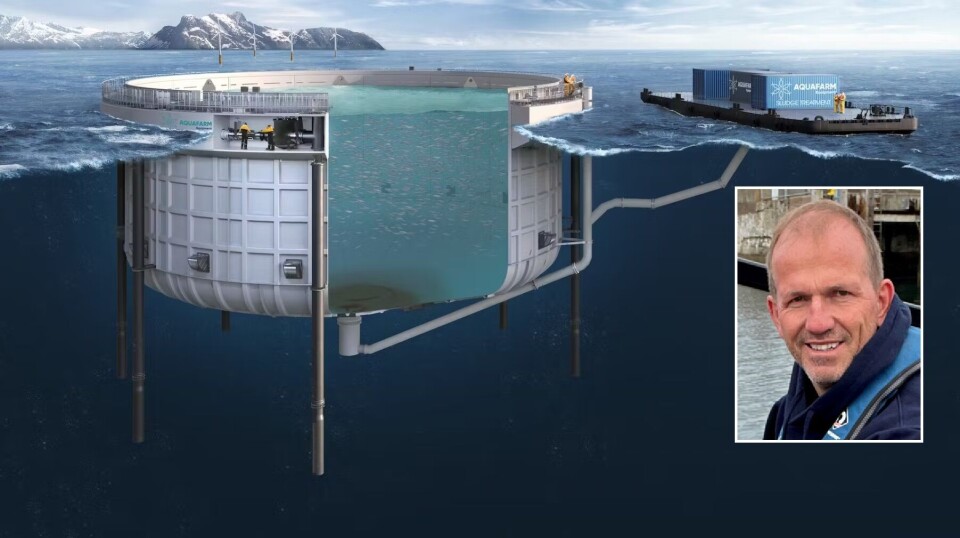

The Aquafarm floating closed system is built from several GRP (glass reinforced plastic) panels. It has a 126-metre circumference, a depth of 22 metres, and a gross volume of 21,000 cubic metres.

Mowi Norway has carried out full-scale testing of the system

for post-smolt production, but it is also designed for growing fish to harvest

size and for brood fish. Mowi Scotland also considered using Aquafarm's Neptune pens for post-smolt production but is for the time being relying on raising them in net pens in Loch Etive, which has low salinity and fewer sea lice than other sea lochs.

Better control

“I have spent much of my career improving framework conditions, securing operations and increasing the rate of innovation in the aquaculture industry. If we are to continue to develop this industry, I am convinced that we must acquire better control over the fish’s environment and water quality,” said Paulsen.

“Aquafarm has impressively developed a sustainable and cost-effective way of improving the aquaculture industry, and I am enormously looking forward to being part of the further work.”

Lønning said Paulsen’s appointment would help to build the company’s commitment to sustainable production in Norway and abroad.

“Our industry must think completely new. About fish welfare. About lice. About escape,” he said. “While we wait in excitement for the (government’s) new environmental technology scheme in Norway, rapid and extensive changes are taking place outside the country’s borders. The demand for sustainable farming is increasing - so is the need for fish. We want to be part of the solution for the sustainable food production of the future and therefore we must be present where the changes happen.”

New finance boss

Aquafarm Equipment has also hired Benedikte Tveit from Alde Akva, an independent consultancy firm providing advisory services within land-based aquaculture facilities and closed sea cages . Tveit will be the company's new chief financial officer.

“Our industry is capital intensive and with Benedikte Tveit we get a person with solid project management experience. She is also a smart business developer,” said Lønning.

The company hopes that the Norwegian government will now finally come up with good incentives for sustainable, closed production and position itself for major changes in the market.

“Many markets and countries are really pressing the gas pedal now, and if incentives for closed systems are not in place soon, Norway will really lose its competitiveness. With Benedicte and Roar on board, we top the team, and are ready both in and outside Norway,” said Lønning.