Killer plant points way to anti-biofouling coating

Scientists have taken inspiration from a carnivorous plant to develop a non-toxic coating that combats biofouling on nets and boats.

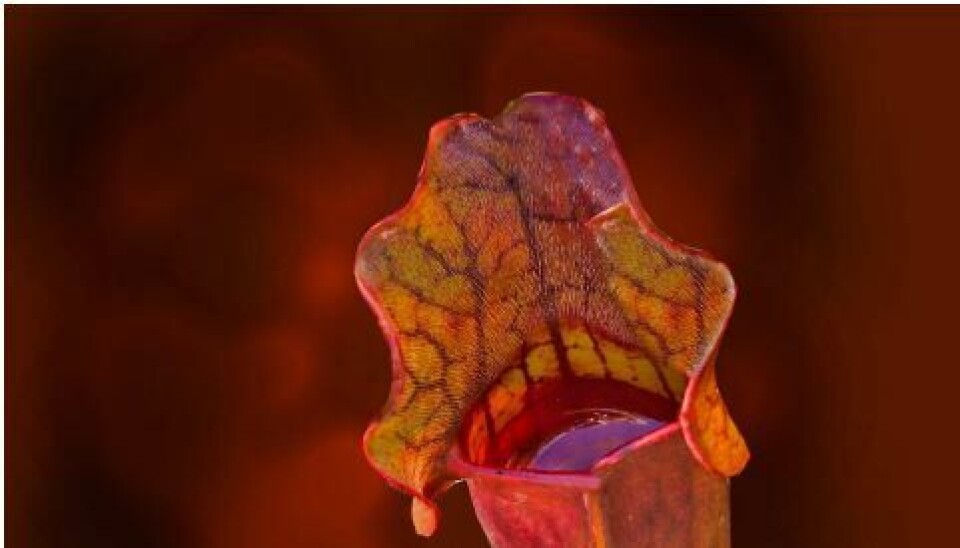

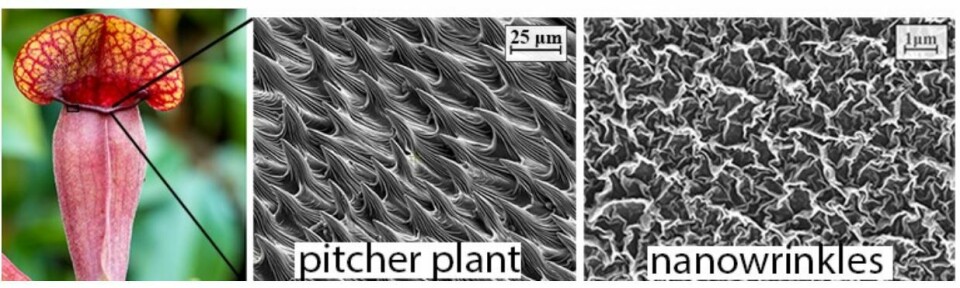

The new coating uses ‘nanowrinkles’ inspired by the carnivorous Nepenthes pitcher plant, reports the University of Sydney. The plant traps a layer of water on the tiny structures around the rim of its opening. This creates a slippery layer causing insects to aquaplane on the surface, before they slip into the pitcher where they are digested.

Biofouling – the build-up of damaging biological material – is a huge economic issue, costing the aquaculture and shipping industries millions of pounds a year in maintenance and extra fuel usage.

Associate Professor Chiara Neto, leader of the research team at the University of Sydney Nano Institute, said: “We are keen to understand how these surfaces work and also push the boundaries of their application, especially for energy efficiency. Slippery coatings are expected to be drag-reducing, which means that objects, such as ships, could move through water with much less energy required.”

Tied to shark netting

In the lab, the slippery surfaces resisted almost all fouling from a common species of marine bacteria, while control Teflon samples without the lubricating layer were completely fouled. The new materials were then tested tied to shark netting for seven weeks in Sydney’s Watson Bay, showing that the nanomaterials were efficient at resisting biofouling in a marine environment.

Nanostructures utilise materials engineered at the scale of billionths of a metre – 100,000 times smaller than the width of a human hair. Neto’s group is developing nanoscale materials for future development in industry.

The interdisciplinary University of Sydney team included biofouling expert Professor Truis Smith-Palmer of St Francis Xavier University in Nova Scotia, Canada, who was on sabbatical visit to the Neto group for a year.

Read the full research article here.