Andfjord focuses on growing capacity instead of fish

Land-based salmon farmer ready for the big time after proving concept with first crop

Andfjord Salmon has harvested its first crop of fish but won’t begin growing a second batch for another year.

Instead, the land-based producer will focus on building up significantly more capacity on the island of Andøya, northern Norway.

Andfjord harvested 800 tonnes (700 tonnes head on gutted) of salmon that grew from 120 grams to an average weight of around 4 kg in 12 months in its pilot pool at Kvalnes, Andøya.

The aims of the first cycle were to prove that its novel form of flow-through technology works and provide documented evidence for authorities that fish welfare was good, both of which have been achieved. Mortality has been approximately 2.2% and the feed conversion ratio has been 0.96.

40,000 tonnes at Kvalnes

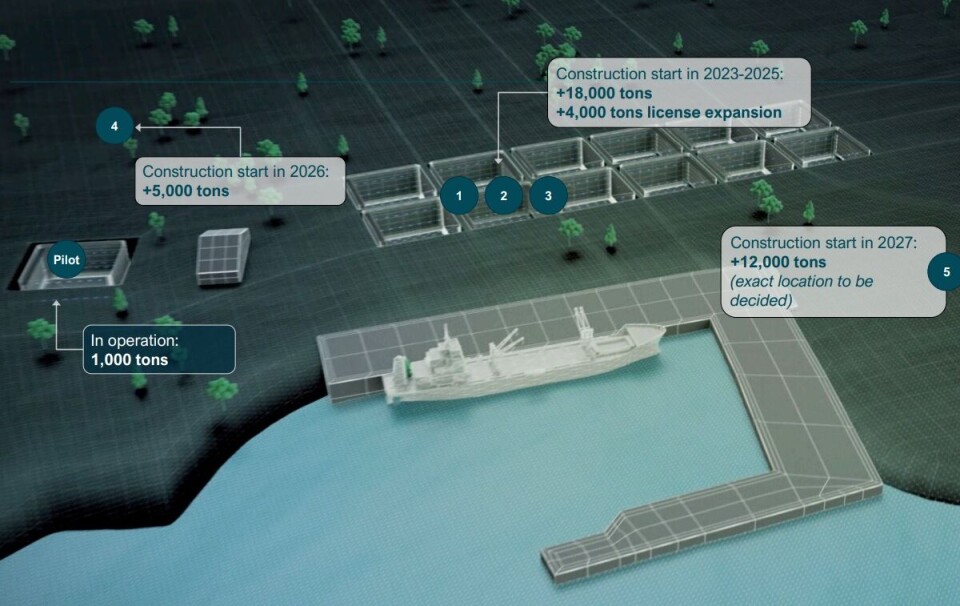

Andfjord’s ambition now is to produce a total of 40,000 tonnes a year - 50 times the volume of its first harvest – at Kvalnes, and a further 50,000 tonnes split between two nearby locations on the northeast section of Andøya’s coast.

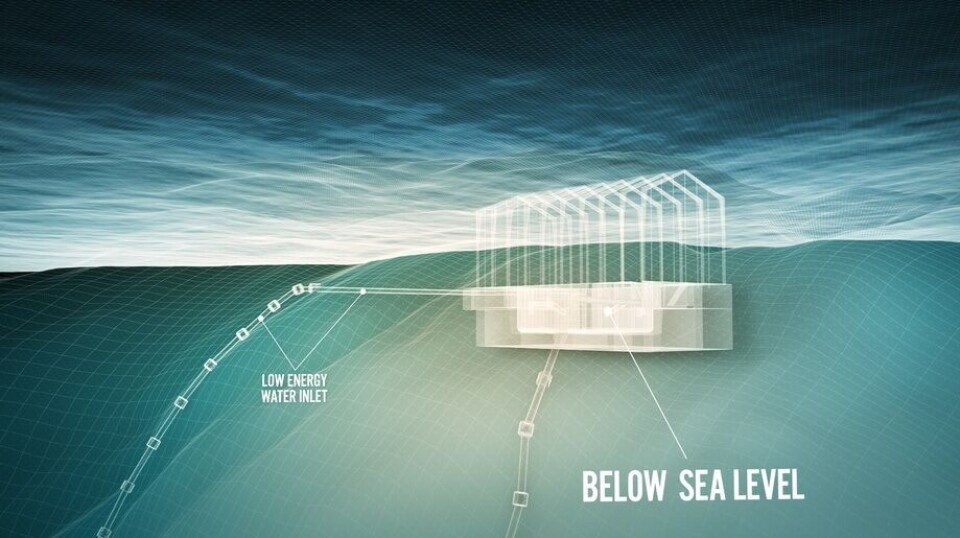

Unlike most other land-based farmers, the company has not chosen above-ground tanks. Instead, it has blasted into the bedrock to a point below sea level. This means that inlet water is not pumped in the traditional sense but is "pushed" in from the sea outside. The pool where the fish go is also not circular, but square and uses laminar flow, where the water enters through portals in one end wall and exits at the opposite end.

“We believe we are perfectly situated, with clean water at the right temperatures,” chief executive Martin Rasmussen told Pål Mugaas Jensen, editor of one of Fish Farming Expert’s Norwegian sister sites, Landbased AQ, when he visited Kvalnes.

Natural habitat

“There are many roads to Rome,” added Rasmussen as he explained why Andfjord Salmon took a different path.

“Some focus on being close to the market by building RAS (recirculating aquaculture system) facilities. We wanted to invest in a model in the salmon’s natural habitat that is close to the way farming has been carried out in Norway for many years. The difference is that we collect the water from 40 metres deep, which in our case provides access to temperate Gulf Stream water, which is collected below the sea level where the salmon lice live.”

Because farming in a laminar water flow had not been done to this extent, authorities required fish welfare throughout the first production cycle to be documented thoroughly by external parties, before a further permanent approval to produce such fish can be obtained.

Higher growth

Andfjord has had this documentation done by the fish health company Åkerblå in collaboration with research institute Nofima. In February, the first interim report came out, which concluded that “overall, the welfare of fish in the system during the first six months of the documentation project has been good in relation to, among other things, the FISHWELL score scheme for input- and outcome-based indicators for salmon”. The report’s authors also pointed out that “growth has been higher throughout the period than what is indicated for fish in this weight and temperature range”.

In relation to the conventional salmon farming growth plan from feed manufacturer Skretting, the fish are 40% larger than if they had been reared in a conventional cage with the temperatures that Andfjord had taken as a starting point before starting the first production cycle. So, the harvest that was originally planned for October ended up happening in June/July.

The feed used is specially developed together with Skretting and among other things contains a lot of marine raw materials, not least from calanus, a type of zooplankton. The feed, together with good management and a low stress level, has resulted in a very good colouring, which at harvest is around 30 on the Salmofan scale.

Less cold

“We also saw that in the cold winter period we had much better growth than expected. The water temperature was 1-3 degrees above traditional farmers in the area,” said Rasmussen.

The company says its use of below sea level pools and a patented technology gives it a low energy consumption of 1 kWh/kg salmon produced. It also claims an industry-leading survival rate of 97.8%.

Last month Andfjord Salmon raised approximately NOK 615 million (£45.2m) in a private placement of shares to expand the company’s production capacity to 40,000 tonnes at Kvalnes.

The company has also secured a NOK 700 million loan from SpareBank 1 Nord-Norge and bank alliance partners for the project, which has a budget of NOK 1.3 billion plus a buffer of NOK 350m.

Andfjord is targeting a blended capital expenditure of NOK 114 per kg (including buffers) and operating expenditures of NOK 40 per kilo salmon produced (including depreciation).