Closed containment salmon farmer sets sights on British Columbia

First Nations support plan and talks with DFO have gone well, says Akvafuture

A Norwegian salmon farming company that uses a proven floating closed containment system is seeking to expand into British Columbia, where Canada’s federal government is seeking to “transition” the sector from open net pens.

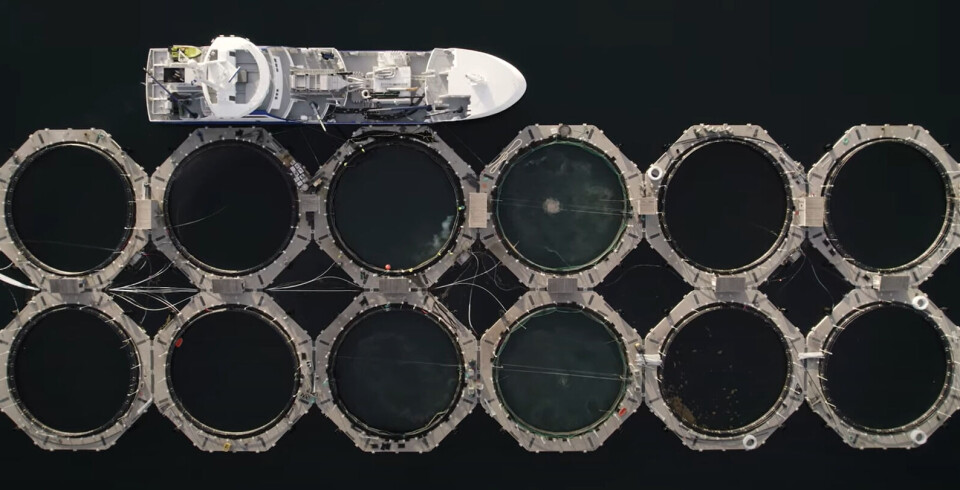

Akvafuture has produced a total of 30,000 tonnes of salmon in five cycles in its self-developed farming system that uses concrete float collars and a 6,000 m³ impermeable bag enclosing a net. The honeycomb design of the collars gives a stronger floating structural advantage.

Oxygenated water is pumped continuously into the enclosures, called Akvapods, from a depth of 20 metres, which is below the layer of the water column where sea lice are found.

Discharge water is filtered to remove fish faeces and sludge, which is dried on site and used for fertiliser and biogas. Akvafuture also grows mussels and kelp at its sites to take advantage of nutrients left in the discharged water after filtering.

Three or four farms

Experienced salmon farmer Dean Trethewey, who spent 15 years with Mowi and was more recently production director for Grieg Seafood BC, runs Akvafuture’s BC operation.

He told Fish Farming Expert that he had identified several sites that have both the renewable electricity supply and water quality required for Akvafuture salmon farms and has the support of First Nations whose traditional territories encompass the potential farm locations.

Akvafuture would initially seek to establish three or four farms which each have a production capacity of 4,000 tonnes. The site tenures would be held by the First Nations, and stocking density is planned to be 30-40 kilos per cubic metre, which Trethewey said had proven to show excellent results.

Renewable electricity

Brønnøysund-based Akvafuture, which farms at three locations, uses hydro electricity from northern Norway’s grid and is also looking to use hydro power in BC as part of its commitment to sustainability.

“Our goal is to remain the lowest CO₂ protein producer in the world. That means we have extensively pursued sites that are within the BC Hydro grid and with excellent water quality. All our pumps are electric, and we also use a system that collects and processes the recovered sludge,” said Trethewey.

If all goes to plan, he hopes to start farming within 18 months.

“We have got support from the DFO (the federal government’s Department of Fisheries and Oceans). They want to transition to this kind of technology,” he said.

“In initial meetings with the government they have been very supportive and are happy to see this kind of technology come along.”

Impact of closures

Trethewey said First Nations and coastal communities in BC were experiencing drastic changes in the salmon farming sector due to recent farm closures by the DFO.

“Our goal is to farm the most sustainable salmon on the market so that the next generation of salmon farmers can continue to grow communities and salmon. One cannot deny the negative impact the closures have on these communities.”

Akvafuture has released a video about its system, which Trethewey hopes will influence thinking in Canada. He pointed out that the pace of technological change in aquaculture meant that he had “never farmed the same way twice” in a long career as a fish farmer.

Catalyst for change

“This video reflects our passion for innovation and our belief that responsible aquaculture can be a catalyst for positive change. We hope to influence politicians and stakeholders, as well as people passionate about the industry, that there are farming practices out there that solve the biggest problems of the industry without the sacrifice of workplaces.

“By integrating biology with engineering, we are creating stronger fish welfare systems and growing the seafood potential in BC. Who knows how the industry will look like 10-20 years in the future, but it will certainly depend on the decisions that are being made right now.”