Plastic patches for fish farm nets save time and money, says developer

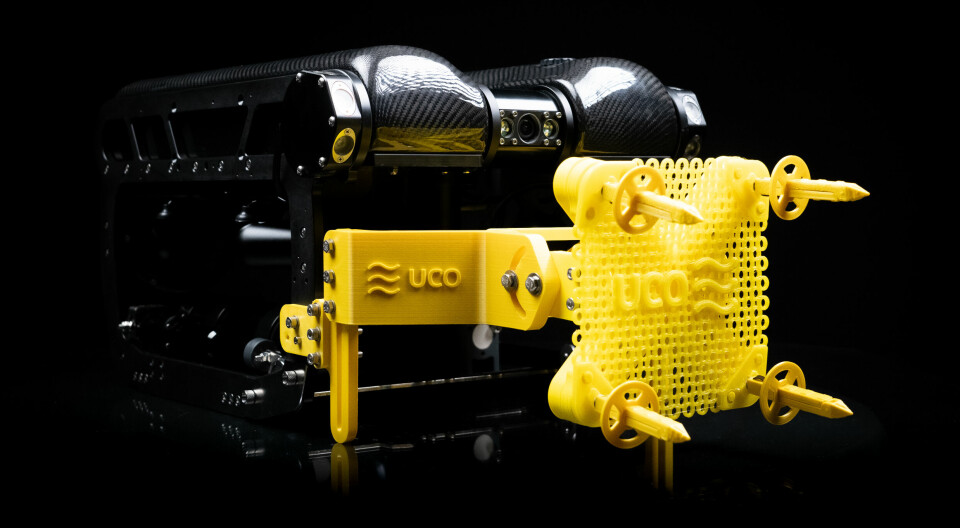

Aberdeen-based Underwater Contracting, which provides remotely operated vehicle (ROV) services to fish farmers, has developed an ROV-deployed system to quickly repair small holes in fish farm nets.

The UCO NetFix repair system places plastic patches over holes in cage netting. Held firmly in position by pegs, the patches remain in place until the hole is permanently repaired by a dive team or when the nets are lifted to the surface.

Small holes, which can be made by predators or if equipment becomes snagged during operations, are identified during routine containment checks by ROV or during net washing. UCO said that until now, these would require calling out a dive team at short notice to carry out repairs, a time consuming and expensive process. NetFix uses the onsite ROV to carry out an immediate repair, ensuring containment of all stock.

Deployed by ROV

Deployed using a frame attached to the inspection class ROV, the semi-permanent repair is compatible with on-going net washing activity as the patch sits flush with the inside of the net. Planned permanent repairs by the dive team can then be scheduled. The patches and plugs, which are easily removed by a diver, are reusable.

The deployment frame can be made to fit any regular inspection ROV. Patch size is 200mm x 200mm with peg size dependent on netting size.

“Breaches of containment damage reputation and can be very costly. NetFix now provides the solution to reduce the risk of lost stock by immediate repair of small holes,” said UCO managing director Mick Bower.

100% containment

“We are fully supportive of the Scottish Government’s aspirations for the future of the sector to 2045 and beyond. One of the ways of demonstrating sustainable aquaculture in the context of environment and biodiversity is to aim for 100% containment.”

UCO is part of Ocean Marine Group, and provides underwater services for aquaculture, oil & gas, and offshore renewable energy sectors.

One of its other aquaculture products is the patented FOOVER Mortality Recovery System, which UCO says is the only system capable of positive confirmation of mortality recovery, providing a visual guarantee and recordable video of the operations being performed. The company also offers high pressure pumps and lances for net washing.

UCO is exhibiting at the Aqua Nor trade show in Trondheim, Norway, next week (22-24 August) as part of the Scottish Pavilion.